- Home

- News

- Spotlight on Science

- A deeper look into...

A deeper look into recrystallisation in heavily deformed metal alloys

02-06-2022

Dark-field X-ray microscopy at beamline ID06-HXM was utilised to investigate microscopic changes in the structure of an industrial alloy during thermal annealing. A deeper understanding of this phenomenon is relevant because the structure determines useful properties such as hardness and ductility.

The industrial processing of metals typically includes techniques such as hot or cold rolling, which puts the metal under stress, causing plastic deformation (permanent changes or dislocations to the material’s crystal lattice structure), followed by thermal annealing. The density and distribution of dislocations in the crystal structure, and the growth of recrystallised grains can determine the brittleness and ductility (and therefore the workability) of a metal, but can also affect properties such as electrical conductivity, magnetic response, resistance to corrosion, etc. Understanding the nucleation and growth of recrystallised grains in deformed materials is therefore of great industrial interest.

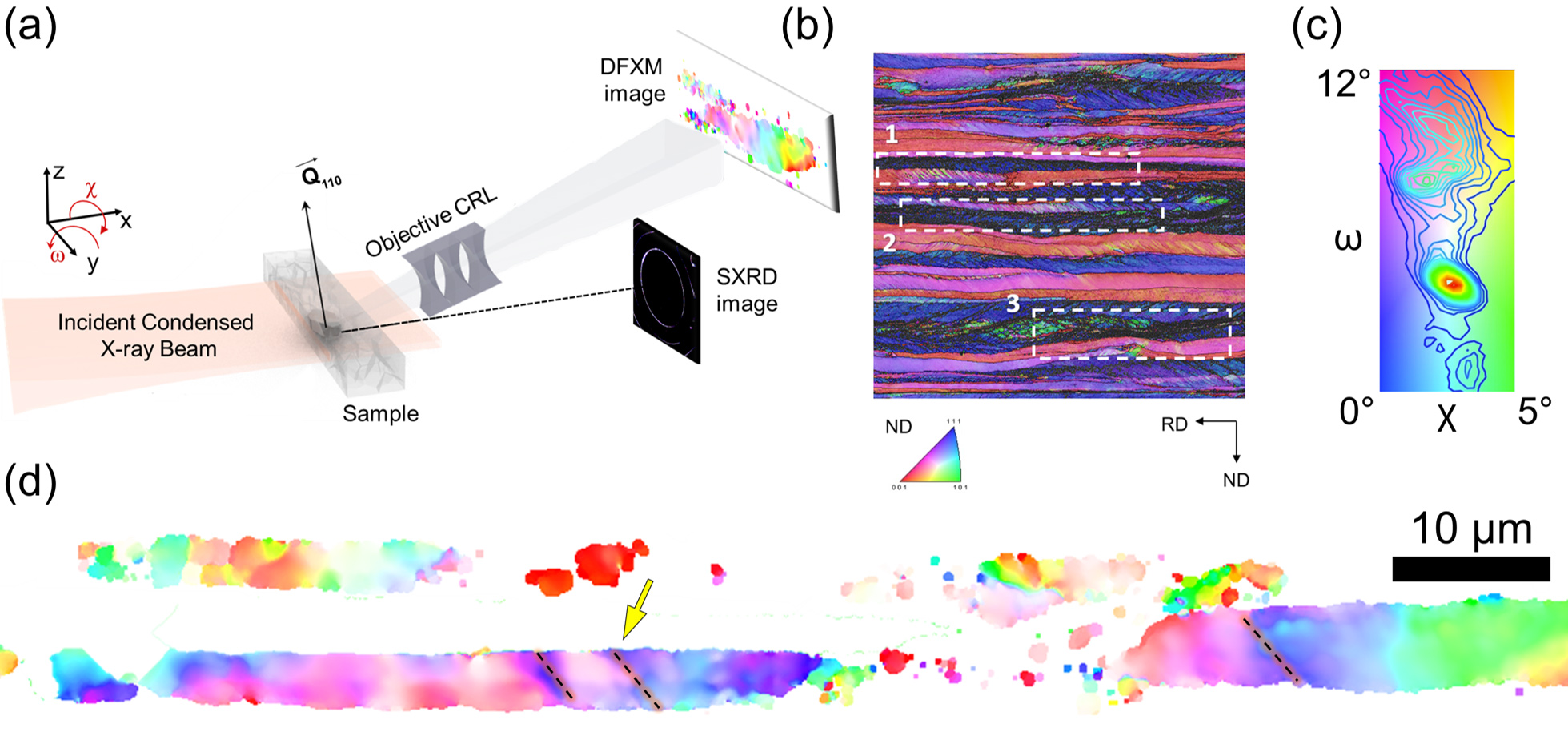

Dark-field X-ray microscopy (DFXM) is a novel X-ray imaging technique enabling the non-destructive mapping of strain and orientation in bulk materials with high spatial and angular resolution [1]. By placing an X-ray objective lens in the diffracted beam path, a diffraction volume can be imaged (Figure 1a). Furthermore, the objective filters out unwanted overlap and stray diffracted signals, thereby focusing on a grain of interest (GOI). The microscope can be coupled with coarser grain methods to obtain grain-averaged strain and texture information.

In this work, DFXM was used at beamline ID06-HXM to investigate recrystallisation of a cold-rolled, heavily deformed (85% reduction in size) ferrous alloy (Fe-3%Si-0.1%Sn) during thermal annealing. The technique revealed the 3D microstructure of the 200µm-thick sample, demonstrating, for the first time, a direct observation of the relation between the deformed matrix and recrystallised grains within high stored energy regions. The results have unveiled the specific preferred orientation patterns of recrystallisation and grain growth paths within these regions, indicating that higher misorientation zones, such as grain boundaries or deformation bands, are preferential grain nucleation regions.

Fig. 1: a) Schematics of DFXM experiment. b) Electron Backscatter Diffraction Normal Direction-Inverse Pole Figure map of the initial microstructure of the as-deformed state through thickness. c) DFXM local {110} pole figure colour key of the two sample tilts. d) DFXM mosaicity map of a selected layer of the as-deformed state. The mosaicity scans at the constant angle reveals the spatial variation of the orientation of {110} plane.

Figure 1d shows the first ever DFXM image of a highly deformed grain, revealing the fine details of the deformed matrix, such as orientation gradients and deformation bands with distinct alignment with respect to the rolling direction. Compressive strains larger than 0.001 are accumulated around these deformations. These high deformation and stress concentration points act as nucleation sites upon annealing.

Figure 2 shows the early stages of recrystallisation. While the orientation gradient observed in Figure 1d is still visible, new recrystallised grains have nucleated within and around the deformed parent grain, with larger intensity and significantly lower orientation spread. Additional recrystallised grains are observed in the close vicinity of the parent grain boundary, while the orientation spread is not directly correlated to the distance from the parent grain.

Fig. 2: Zoom into the early stages of recrystallisation via DFXM maps after 190s annealing at 610°C of the embedded GOI. a) Mosaicity and orientation distribution colour key. Some of the recrystallised grains are marked with red arrows in the local pole figure. b) Misorientation map emphasising the boundaries and cells (log scale). Yellow arrows show the nucleation sites and the red arrow marks the bulging of a new recrystallised grain into another deformed grain with a different orientation. c-f) DFXM in-situ monitoring of recrystallisation and grain growth in an embedded GOI during annealing at 610°C.

In summary, by means of DFXM, an extensive 3D movie has been made of the nucleation and relation of the growth of recrystallised grains with the surrounding matrix in a heavily deformed industrial alloy. DFXM proves a significant tool for capturing both the structural and the dynamic evolution of recrystallisation in-situ and in real-time. This opens up new avenues in understanding that have industrial significance for the control of material microstructure in order to tailor properties, and can also be used as input for computational growth models.

Principal publication and authors

4D microstructural evolution in a heavily deformed ferritic alloy: a new perspective in recrystallisation studies, C. Yildirim (a), N. Mavrikakis (b,c), P.K. Cook (a), R. Rodriguez-Lamas (a), M. Kutsal (a,d), H.F. Poulsen (d), C. Detlefs (a), Scripta Materialia 214, 114689 (2022); https://doi.org/10.1016/j.scriptamat.2022.114689

(a) ESRF

(b) Aix-Marseille University, Institut Matériaux Microélectronique Nanosciences de Provence-IM2NP, UMR (France)

(c) ArcelorMittal Global R&D Gent, Zelzate (Belgium)

(d) Department of Physics, Technical University of Denmark, Lyngby (Denmark)

References

[1] C. Yildirim et al., MRS Bulletin 45, 4 (2020).

|

About the beamline: ID06-HXM |