- Home

- Industry

- Industry news

- How do safety foams...

How do safety foams deform in cars?

29-11-2016

Jaguar Land Rover and the University of Warwick have studied automotive safety foams using microtomography at the ESRF. The goal: to improve the performance of foams to reduce the forces the passenger experiences upon impact.

Share

Company

Jaguar Land Rover and University of Warwick

Challenge

Energy absorption is important for the safety of car passengers. Besides the seat foam used for comfort, modern vehicles have a denser foam such as expanded polypropylene (EPP) inside headrests and bumpers that decelerates passengers in such a way as to minimise any stresses on them. Ideally, a foam would do this by deforming in a controlled manner, reducing the maximum forces experienced by the occupant.

Sample

Expanded polypropylene used in cars.

Solution

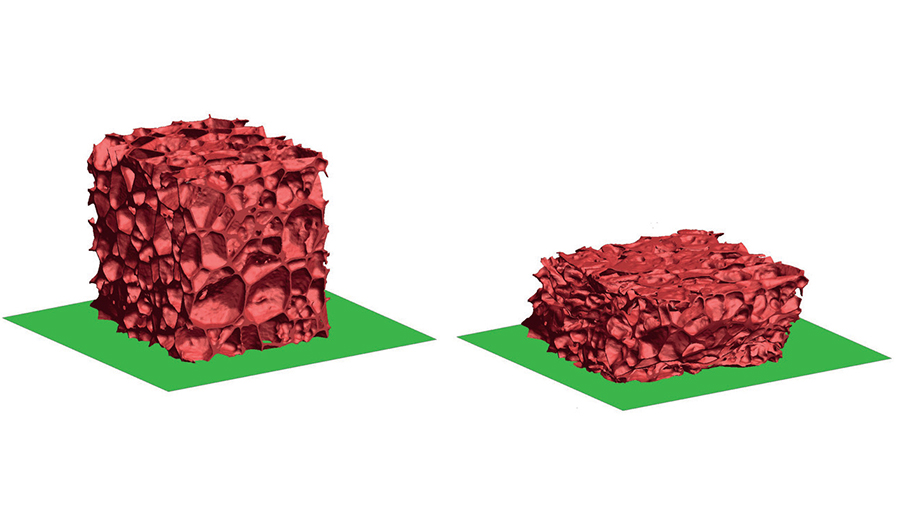

The researchers studied EPP’s energy-absorption properties under deformation at the ESRF, using new material models to improve a computer-aided design process. At the beamline ID19, the researchers performed microtomography, which enabled them to continually image their EPP foams (see figure above) as they were slowly compressed with a dedicated press facility. Incorporating the images into a three-dimensional computer model, the researchers could analyse them to understand how to improve the foam, and how much of it to use in a vehicle for optimal performance.

Benefit

The benefit of the ESRF in this research was the ability to track the deformation in situ an in great detail. “The facilities available at the ESRF will allow us to improve the use of polymer foams as energy absorbers in our vehicle range”, expalins Mark Blagdon, a materials engineer who led the project from Jaguar Land Rover.

|

| Microtomography reveals how safety foam disperses energy under load for car headrests. |