- Home

- Industry

- Industry news

- Standardisation...

Standardisation of industrial residual stress characterisation: EASI-STRESS

08-03-2022

Since the beginning of 2021, Industry at ESRF has been engaged in the EU-project EASI-STRESS with partners from industry, academia and research and technology organisations. EASI-STRESS is now picking up speed: scientists are examining the first samples at the participating research institutes.

Share

There have always been various ways of working metals. For example, they can be forged, welded, cast or additively manufactured. In all these processes, residual stresses are generated in the material. But residual stresses in metals may lead to catastrophic failures under fatigue processes. Therefore, residual stresses are of key importance across all industrial sectors where metals are used, e.g. within the transportation and energy sectors. Such residual stresses can be investigated using various methods including neutrons and synchrotron X-rays, which penetrate into metals and alloys and enable non-destructive direct determination of bulk stresses.

Insufficient comparability

In the past, industrial developers have struggled to utilise synchrotron X-ray and neutron diffraction-based residual stress characterisation tools due to insufficient data comparability and lack of harmonised protocols. This made it difficult to confirm reproducibility and traceability of the measurements. “We aim at lowering these barriers for industry by setting up European-wide standards and operating procedures and harmonising data formats,” explains project coordinator Dr. Nikolaj Zangenberg.

|

|

Standardisation of stress characterisation to help innovation in industry (image credit: DTI). |

The EASI-STRESS project wants to support companies in analysing and improving their materials in the best possible way. With the help of the measurements, the industry can better predict and control stresses in materials and thus optimise the design of components. It is also sustainable: those who know their materials well can reduce material consumption or shorten time to market by qualifying new materials or processes more quickly.

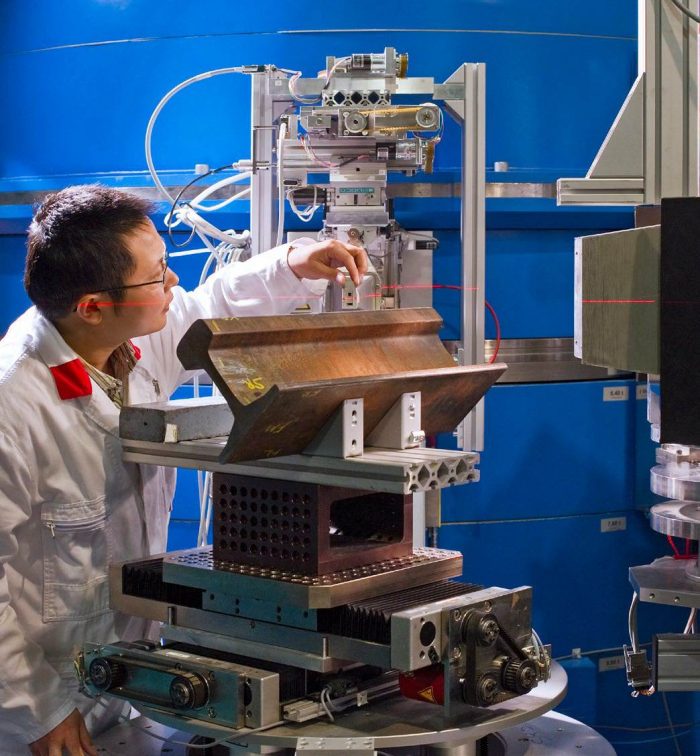

Since November 2021, the project partners have been performing residual stress measurements on newly-developed round robin samples. The samples are being measured at the European Synchrotron Radiation Facility ESRF and Institut Laue-Langevin (both in Grenoble), at instruments of Helmholtz-Zentrum Hereon at DESY (Hamburg) and at Budapest Neutron Center BNC (Budapest), using relevant standardised laboratory techniques. The results will be compared to modelling data. The samples have been designed to replicate different industrially processed materials that will, at a later stage in the project, also be investigated in real industrial components through case studies defined by the industrial partners.

|

|

A Hereon scientist examines samples at FRM II, the research neutron source at the Heinz Maier-Leibnitz Center. (image credit: Andreas Heddergott / TU München). |

The goals of EASI-STRESS

- to improve synchrotron X-ray and neutron diffraction-based residual stress characterisation tools for the needs of industrial use

- developing European-wide characterisation standards, protocols and data exchange procedures to facilitate the industrial use of the characterisation tools, e.g. through traceability and comparability

- strengthening European industrial uptake of the characterisation tools through open access to data and protocols, development of a test bed service and collaboration/synergy/standardisation activities

- to secure a competitive advantage across European industrial sectors through optimised component design, reduced material use through reduced safety factors (material savings of around 15%) and an estimated cost-reduction of 5% in a EUR 350 billion market through shortened time-to-market, and increased lifetime

The EASI-STRESS consortium

Research Infrastructures: Institut Laue-Langevin (FR, GER, UK), European Synchrotron Radiation Facility (FR), Helmholtz-Zentrum Hereon (GER), Centre for Energy Research (HU)

Universities and Research and Technology Organisations: Danish Technological Institute (DK), University of Manchester (UK), CETIM (FR)

Industry: Siemens Gamesa (DK), Rolls Royce PLC (UK), OHB Systems AG (GER), Volume-e (FR), Arcelor Mittal (ESP), Nemak (AU), EDF (FR)

Standardisation body: Dansk Standard (DK)

More information at: www.easi-stress.eu

Follow us on

Twitter: @EASI_STRESS

LinkedIn: https://www.linkedin.com/showcase/75054908