- Home

- Users & Science

- Find a beamline

- Electronic structure, magnetism and dynamics

- ID28 - Inelastic Scattering II

- Beamline Layout

- Optical Hutch 1

- Collimating compound refractive Beryllium lenses

Collimating compound refractive Beryllium lenses

Collimating compound refractive Beryllium lenses

A set of four compound refractive x-ray lenses (CRL), made out of Beryllium, is installed in OH1 at a distance of 28.5 m from the source point. Their role is threefold: (i) collimation of the x-ray beam in order to better match the spectral angular acceptance of the high-heat load silicon (1 1 1) monochromator, (ii) to provide a smaller footprint on the toroidal mirror so that a better focal profile can be obtained, and (iii) to keep a the beam height in the vertical plane small, so that the focusing CRL (located at 94 m from the source point) has a reasonable efficiency (for more details see section on the focusing CRL).

Since the index of refraction n = 1 –  – i

– i  for x-rays is smaller than unity, the lens has a concave shape (as opposed to a convex shape in visible optics). Furthermore, the focusing effect of a single lens isvery small due to small deviation from one of the refractive index (10-5 – 10-7). Many lenses have to be therefore put one behind each other.

for x-rays is smaller than unity, the lens has a concave shape (as opposed to a convex shape in visible optics). Furthermore, the focusing effect of a single lens isvery small due to small deviation from one of the refractive index (10-5 – 10-7). Many lenses have to be therefore put one behind each other.

For a collimating lens (image at infinity, q =  ), the lens equation reads as follows:R/N=2

), the lens equation reads as follows:R/N=2  p

p

where R is the radius of the hole, N the number of holes,  is the refractive index decrement, and p the distance between the source and the lens.

is the refractive index decrement, and p the distance between the source and the lens.

Table X summarises the characteristics and performance of the collimating CRL’s.

| Si(n,n,n)

Reflection |

N holes

R = 1 mm |

Transmission | sz’

[  rad] rad] |

gain |

|---|---|---|---|---|

| 8 | 13 | 0.96 | 2.3 | 1.02 |

| 9 | 16 | 0.92 | 3.0 | 1.06 |

| 11 | 24 | 0.90 | 1 | 1.20 |

| 13 | 34 | 0.92 | 1.9 | 1.29 |

s z’ denotes the experimentally determined residual vertical divergence, and the gain corresponds to the increase of flux at the sample position. The web thickness in the center axis of the lens is 0.1 mm.

|

|

|

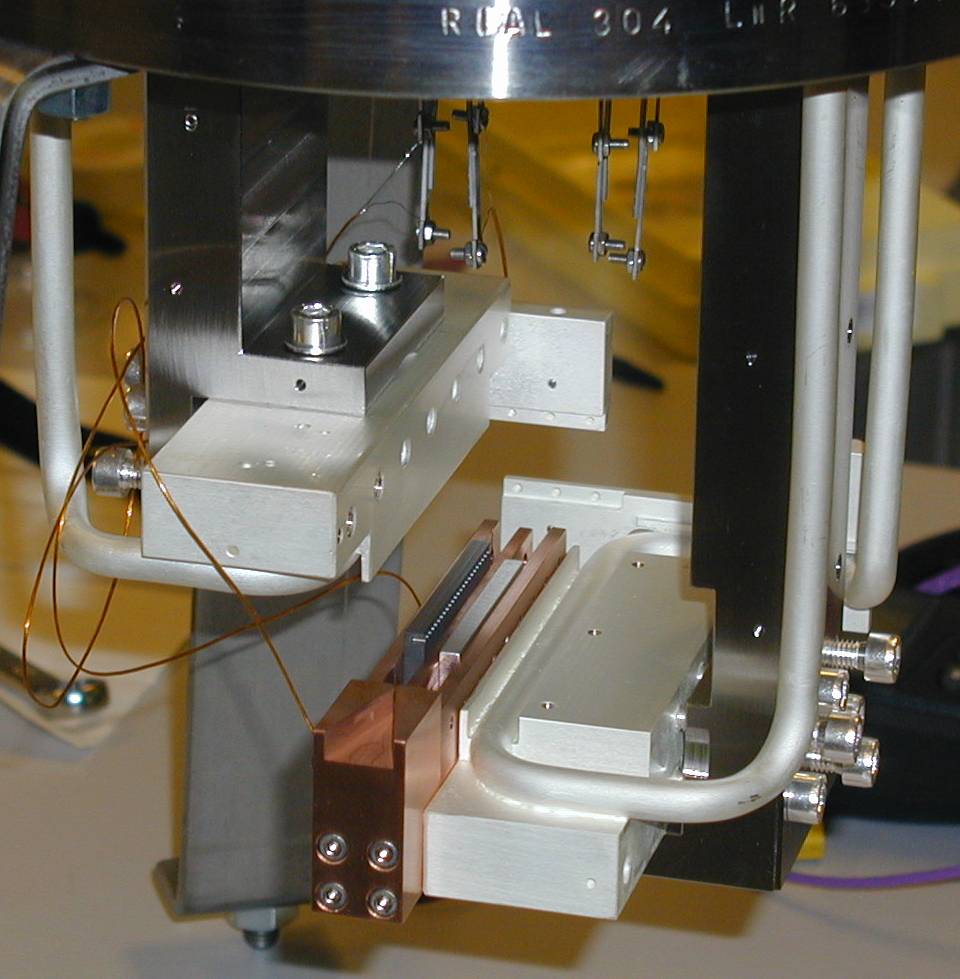

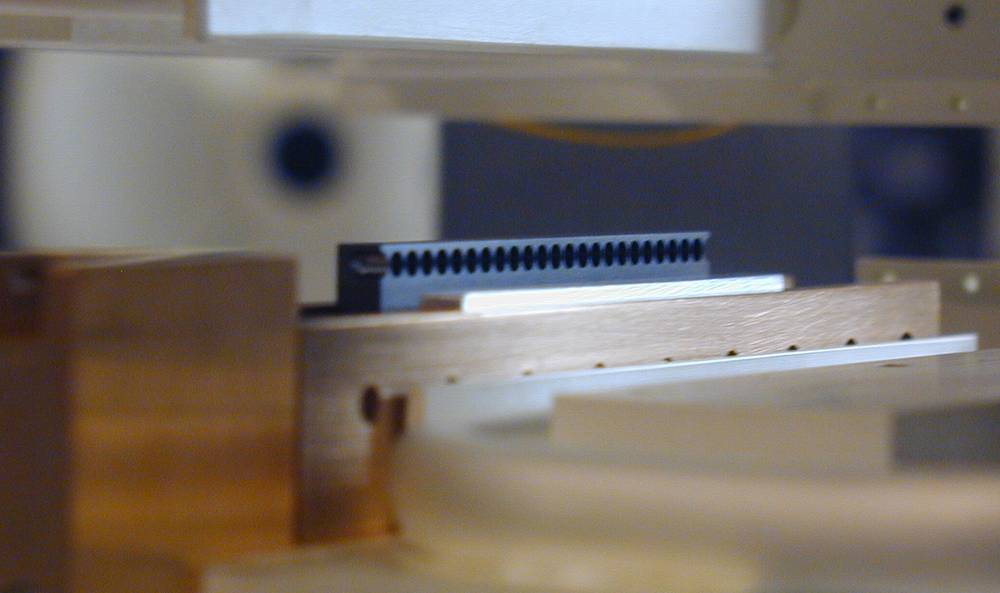

View of the CRL Be Lenses in the assembling operations.