- Home

- Users & Science

- Scientific Documentation

- ESRF Highlights

- ESRF Highlights 2010

- X-ray imaging

- Real-time study of roughness evolution of Si surfaces upon ion erosion

Real-time study of roughness evolution of Si surfaces upon ion erosion

The analysis of the Si surface roughness evolution under ion treatment and the determination of parameters to preserve or improve the surface smoothness are increasingly important for advanced reflective X-ray/extreme ultraviolet (EUV) optics. Ion etching is used during the fabrication of such optics to figure a macroscopic Si substrate with sub-nanometre accuracy while maintaining the microscopic roughness at an atomic level.

The evolution of the surface topography upon etching is determined by competing roughening and smoothening mechanisms with different spatial-frequency and time dependencies. A growing or eroding surface can often be described within the theoretical framework of surface dynamic scaling, where the scaling exponents α and β are the signatures in space and time of the growth or etch processes. By comparing the experimental scaling exponent values to the theoretical predictions, one can establish a differential equation describing the growth or erosion. Being a universal description of the ion erosion of Si surfaces, such an equation would contribute tremendously to the understanding of the dynamics for ion-eroded surfaces, and provide the ultimate tool for the selection of etch settings that lead to the best smoothening results.

In situ, real-time information about the roughness evolution of Si surfaces upon Ar ion erosion was obtained from X-ray scattering (XRS) measurements. Diffuse scatter patterns (scattering diagrams) were recorded with a CCD camera at the grazing incidence X-ray reflectometry setup at the BM05 beamline. A microwave electron cyclotron resonance plasma source provided Ar ions for sample erosion. The angle of incidence was 55° with respect to the sample surface (a Si wafer). In two experiments the sample surface was roughened beforehand, so that the effect of the initial roughness on the roughness evolution could be studied.

According to first order perturbation theory, the scattering diagram as a function of the scattering angle is proportional to the power spectral density (PSD) function of the surface roughness as a function of the spatial frequency ν. At high spatial frequencies, the PSD-function behaves as PSD(ν) ~ 1/ν1+2α. This asymptotic behaviour was used to determine the static scaling exponent α, which characterises the saturated roughness. For the previously roughened samples etched at 300 and 1000 eV, we found α = 0.30 ± 0.05 and α = 0.23 ± 0.08, respectively. Therefore, within the experimental error we conclude that α is independent of the ion energy. For the not-roughened sample, α is not clearly defined in the spatial frequency range measured in this experiment.

|

|

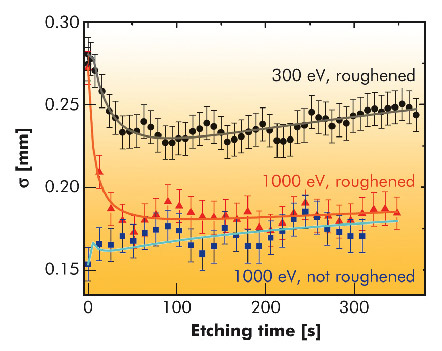

Fig. 139: The evolution of the root-mean-square roughness σ upon etching, for three samples. The solid lines represent the best fits to Equation (1). |

Figure 139 shows the evolution of the root-mean-square roughness σ for three samples, as obtained by integration of the PSD over the measured spatial frequency range. To take into account both the initial roughness of the substrate σS disappearing with the erosion time, and the etching induced roughness σE following the scaling law σE(t) ~ tβ, Majaniemi et al. suggested the following formula in Ref. [1]:

where β is the dynamic scaling exponent, and A and tS are fitting parameters.

The solid curves in Figure 139 are the result of fitting σ2(t) according to Equation (1). The evolution of the rms roughness of all samples is described properly with this equation. The same set of fitting parameters, with β = 0.07 ± 0.01 is used for both the roughened and the not-roughened sample etched at 1000 eV. This shows that the Majaniemi model explains smoothening as well as roughening, depending on the initial roughness of the substrate. In contrast to α, the dynamic scaling exponent β was found to be energy-dependent, as β = 0.14 ± 0.02 at 300 eV.

In summary, we analysed the roughness evolution of Si substrates upon Ar ion etching. Both smoothening and roughening have been observed, depending on the initial substrate roughness. The scaling exponents α and β, important parameters for the determination of a comprehensive theory of ion erosion of (Si) surfaces, have been determined.

Principal publication and authors

V.I.T.A. de Rooij-Lohmann (a), I.V. Kozhevnikov (b), L. Peverini (c), E. Ziegler (c), R. Cuerno (d), F. Bijkerk (a,e) and A.E. Yakshin (a), Applied Surface Science 256, 5011–5014 (2010).

(a) FOM Institute for Plasma Physics Rijnhuizen, Nieuwegein (The Netherlands)

(b) Institute of Crystallography, Moscow (Russia)

(c) ESRF

(d) Universidad Carlos III Madrid, Leganes (Spain)

(e) MESA+ Institute for Nanotechnology, University of Twente, Enschede (The Netherlands)

References

[1] S. Majaniemi, T. Ala-Nissila and J. Krug, Phys. Rev. B 53, 8071-8082 (1996).