- Home

- Users & Science

- Scientific Documentation

- ESRF Highlights

- ESRF Highlights 2016

- Structure of materials

- Mapping the front of a localised deformation band in NiTi wire with 3D-XRD

Mapping the front of a localised deformation band in NiTi wire with 3D-XRD

The nature of localised superelastic deformation of NiTi wires in tension has been revealed with the help of the 3D-XRD method.

Although polycrystalline solids usually deform homogeneously, some materials tend to form macroscopic bands in which inelastic deformation is localised. These bands may form at the onset (Lüders bands) or at the end (shear bands) of plastic deformation. The interface between the deformed and undeformed material (band front), where the material continuity and strain compatibility has to be maintained, can be either mobile (Lüders bands) or sessile (necking). Localised deformation has always attracted the attention of mechanical engineers as well as theoreticians involved in the modelling of material deformation. Strain localisation is intrinsically a macroscopic phenomenon, governed by the rules of mechanics, though actual deformation mechanisms as well as the microstructure and texture of the material are known to play a role.

As an example, superelastic deformation of NiTi shape memory alloy under tension proceeds frequently via the propagation of martensite band fronts [1,2]. In flat sheet samples, the interface between the deformed and undeformed material is planar, sharp and inclined at an angle of about 55° to the loading direction. The front spreads over thousands of polycrystal grains. For wires and bars, however, the interface appeared to be broad and perpendicular to the loading direction [3], which was curious. Since the martensite band front in superelastic NiTi disappears on unloading, conventional microscopic methods could not be used to reveal the shape of the buried interface. Internal stresses around the moving fronts were completely unknown.

|

|

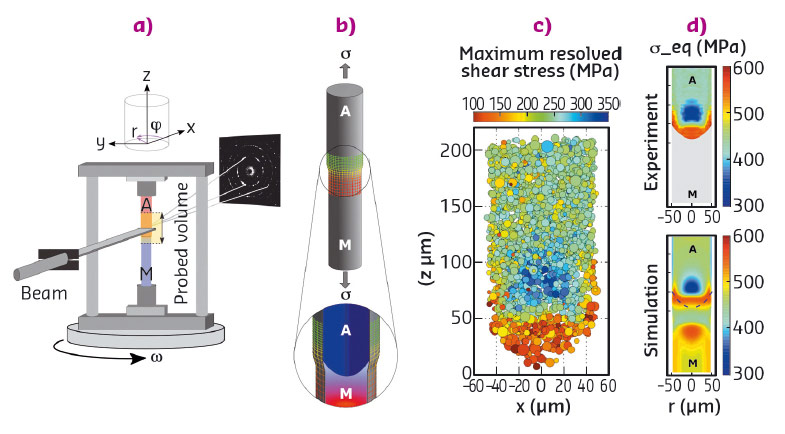

Fig. 67: The 3D-XRD method was used to evaluate grain microstructure and grain-resolved stresses within a martensite band front propagating in a polycrystalline NiTi wire exposed to external stress. |

High-energy synchrotron X-rays are an ideal tool to look deep inside bulk materials during loading tests [4]. By applying the 3D X-ray diffraction method, 3D-XRD (Figure 67a), at beamline ID11, we managed to determine the full strain and stress tensors in ~15000 austenite grains (mean grain size 5.9 µm) within a martensite band front (Figure 67b-d) in a 0.1 mm diameter NiTi wire stabilised by the applied tensile stress of ~420 MPa (Figures 67, 68).

|

|

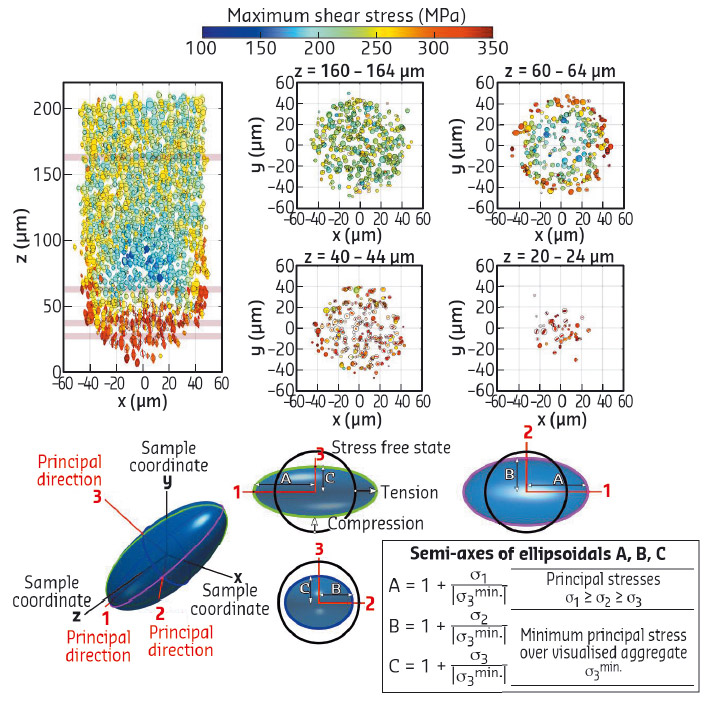

Fig. 68: Stress states in polycrystal grains of tensioned NiTi wire visualised using a tensor imaging approach (stress glyph). Ellipses visualise stress tensors in grains as 2D projections of ellipsoids with semi-axes A,B,C in the principal stress directions. The shape and inclination of an ellipse denote stress state in a single grain, colour denotes the maximum shear stresses and the black circle denotes the size of a grain at a given position. |

The martensite band front has a shape of a buried nose cone internal interface surrounded by an internal stress field (Figure 67b-d). It appeared that the local stresses in grains ahead of the advancing front redistribute in such a way that the grains located at the interface experience very different stress states (Figure 68) compared to the grains far from the interface (~200 MPa higher effective stresses). Consequently, the grains within the front transform collectively, while very little is happening elsewhere. The widespread assumption in the literature that the martensitic transformation in NiTi wire takes place under nominal tensile stress F/S0 was thus shown to be incorrect. Because the superelastic deformation via the martensitic transformation is limited to a few percent by the crystallography, the martensite band front moves under constant force along the wire (Figure 69).

|

|

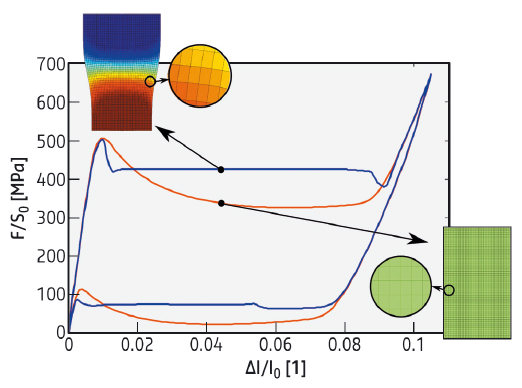

Fig. 69: Stress-strain response of superelastic NiTi wire in tension simulated by an FE implemented SMA model [5] - macroscopic response (blue curve) and constitutive response in each material point (red curve). |

Superelastic deformation of NiTi wire was also simulated by a finite element implemented constitutive shape-memory alloy model adapted for nonlocal effects [5]. Force - elongation response was predicted (Figure 69) and the moving front was reconstructed (Figure 67d) confirming the sharp internal stress gradients.

Principal publication and authors

Grain-resolved analysis of localized deformation in nickel-titanium wire under tensile load, P. Sedmák (a,b), J. Pilch (a), L.Heller (a), J. Kopeček (a), J. Wright (c), P. Sedlák (d), M. Frost (d) and P. Šittner (a), Science 353, 559-562 (2016); doi: 10.1126/science.aad6700.

(a) Institute of Physics of the CAS, Prague (Czech Republic)

(b) FNSPE CTU, Prague (Czech Republic)

(c) ESRF

(d) Institute of Thermomechanics of the CAS, Prague (Czech Republic)

References

[1] J.A. Shaw, Int. J. Plast. 16, 541–562 (2000).

[2] P. Šittner et al., J. Mech. Phys. Solids 53, 1719–1746 (2005).

[3] L. Dong et al., Int. J. Solids Struct. 80, 445–455 (2016).

[4] H.F. Poulsen, Three-dimensional X-ray Diffraction Microscopy: Mapping Polycrystals and Their Dynamics Springer, Berlin (2004).

[5] P. Sedlák et al., Int. J. Plast. 39, 132–151 (2012).