- Home

- News

- Spotlight on Science

- Revealing the internal...

Revealing the internal mechanics of an operating lithium battery via high speed X-ray computed tomography and digital volume correlation

17-12-2015

High speed synchrotron X-ray computed tomography (CT) was used to capture the morphological evolution of active materials within a commercial Li/MnO2 battery during discharge. Temporal 3D strain profiles of the MnO2 electrode were generated via digital volume correlation of sequential 3D tomograms, providing insight into local Li+ transport and interactions between the active material and the cell’s mechanical design.

Share

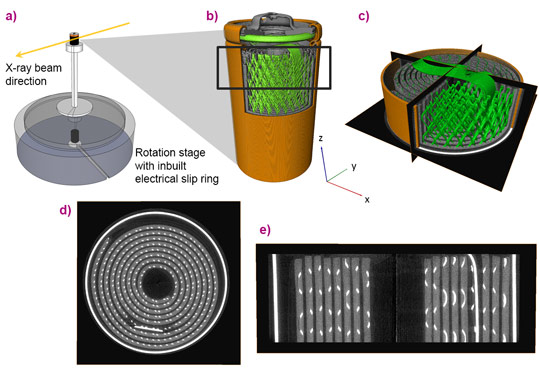

Lithium batteries are the energy storage device of choice for mission critical systems such as emergency signal transmitters as well as rescue, military and space exploration applications. Improving the performance, safety and reliability of lithium batteries is a priority for these batteries which are expected to operate autonomously for extended periods of time, often in extreme environments. A major cause of performance loss within commercial cell designs is the unfavourable interaction between the changeable morphology of electrode materials and the rigid mechanical design of commercial cells. For example, the expansion and contraction of active materials during operation can result in severe delamination and contact loss between the electrode and the current collector, causing impedance of the cell, and internal heating to rise. Understanding the cause of electrode detachment and performance loss within a particular cell design requires non-destructive, local measurements of activity and morphological evolution. In this way, the electro-mechanical effect of the active materials on the cell design can be further understood. Here, we use the unique high speed imaging capability of ID15A to image large portions of a commercial cell, in 3D (see Figure 1), and over very short time spans (2.5 s) during operation. This study builds upon previous high speed imaging experiments at ID15A during catastrophic failure [1].

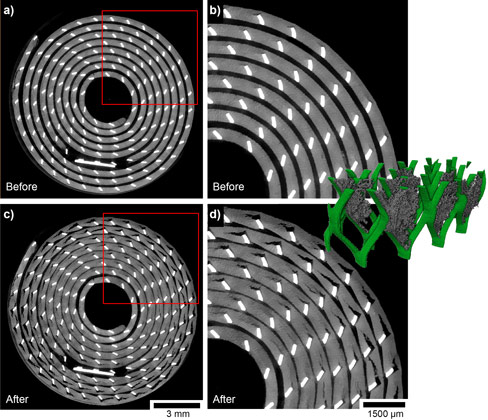

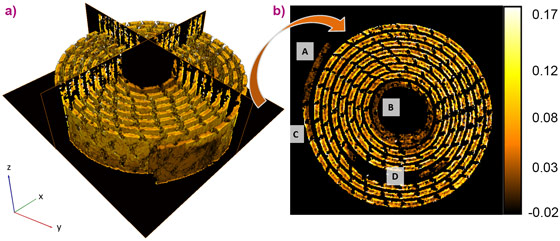

Sequential tomograms, captured continuously during discharge of the cell, reveal electrode materials undergoing a large degree of volume change. The mechanical effect associated with such volume change is seen to cause displacement of the rigid current collector, leading to severe delamination and electrical contact loss (Figure 2). To further understand the nature of this morphological evolution, consecutive tomograms captured via high speed CT were coupled with digital volume correlation (DVC) software developed by Hall et al. [2,3] and Bay [4]. DVC displacement and strain analyses rely on correlating consistent identifiable grain texture in consecutive images, which require images to be acquired at sufficiently short intervals to avoid excessive changes. Three dimensional strain profiles (Figure 3), generated by correlating consecutive images via DVC, present a quantitative view of the local material displacement.

This technique was applied to sequential tomograms captured throughout the discharge process, bringing about time-lapse 3D strain profiles, (or “4D strain”), of the active materials during battery operation. Local strain measurements highlighted numerous inefficiencies and causes of performance loss within the cell. For example, inactive regions where no lithium transport occurs were identified, highlighting the presence of unused electrode material (regions A and B in Figure 3b); the electrode was also shown to be mass transport limited by elucidating the direction (from surface to current collector) in which lithiation induced dilation occurs. Additionally, the local strain was shown to be highly non-uniform and asymmetric between the surfaces of the electrode layers which suggests that one side of the electrode is under-utilised.

The interaction between the volumetric expansion of the electrode and the mechanical design of the cell was assessed by using a separate DVC approach, which measured the extent and direction of displacement of the rigid current collector. The spiral wound current collector mesh (shown in Figure 1) was found to unravel during discharge of the cell. This is thought to be the primary cause of both the propagation of severe cracks within the electrode and the reduction of electrical contact between the electrode and current collector.

This combined approach of high speed operando X-ray CT and DVC is an effective diagnostic tool for identifying causes of performance loss within operating commercial cell designs, while also providing valuable information for multi-physics modelling. By providing a window into the internal mechanics of operating batteries, it is expected that this approach will guide the optimisation and development of commercial cell designs.

Principal publication and authors

Quantifying bulk electrode strain and material displacement within lithium batteries via high-speed operando tomography and digital volume correlation, D.P. Finegan (a), E. Tudisco (b), M. Scheel (c,d), J.B. Robinson (a), D. Taiwo (a), D. Eastwood (e), P. Lee (e), M. Di Michiel (c), B. Bay (f), S. Hall (b), G. Hinds (g), D.J.L. Brett (a) & P.R. Shearing (a), Advanced Science (2015); doi: 10.1002/advs.201500332.

(a) Department of Chemical Engineering, University College London (UK)

(b) Division of Solid Mechanics, Lund University (Sweden)

(c) ESRF

(d) Synchrotron Soleil, L’Orme des Merisiers (France)

(e) Manchester X-ray Imaging Facility, University of Manchester (UK)

(f) Research Complex at Harwell, Harwell Oxford (UK)

(g) School of Mechanical, Industrial and Manufacturing Engineering, Oregon State University (USA)

(h) National Physical Laboratory (UK)

References

[1] D.P. Finegan et al., Nature Communications 6, 6924 (2015).

[2] S. Hall et al., Granular Matter 12, 1-14 (2010).

[3] S.A. Hall et al., Géotechnique 60, 315-322 (2010).

[4] B.K. Bay et al., Experimental Mechanics 39, 217-226 (1999).

Top image: Wear and tear inside a commercial battery revealed by high speed synchrotron X-ray computed tomography