- Home

- News

- Spotlight on Science

- Iridescent flexible...

Iridescent flexible films see the light of day

03-06-2016

Stacking microscopic marbles into regular layers produces intriguing materials that scatter light in such a way that they produce intense colours. A team led by the University of Cambridge and including scientists from Germany, the Netherlands and Japan, has invented a way to make sheets of such a material on an industrial scale, opening up applications ranging from smart clothing for people and smart decoration for buildings, to banknote security.

Share

Systematically-ordered photonic microstructures create ‘structural colour’, i.e. colours that originate from Bragg reflections of visible light. Examples can be found in nature, including opal gemstones, butterfly wings, and beetles, but similar materials have been hard to make artificially on a large scale using techniques that are cheap enough to allow their widespread application.

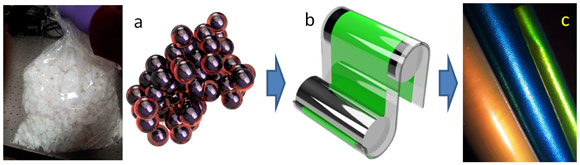

Fabrication of the new materials starts by growing vats of transparent plastic nanospheres that are solid in the middle but sticky on the outside. They scatter all components of the light spectrum randomly while in the disordered state, leading to the milky appearance of the material (Figure 1a). The particles are then pushed together into a thin polymer film using a standard extrusion-rolling-lamination procedure. The outer shells of the particles merge and form a softer polymer medium, in which hard plastic balls, the core part of the original particles, are dispersed. The key for particle ordering is the application of bending-induced oscillatory shear (BIOS) when the film is passed through a number of rollers at an elevated temperature (Figure 1b). Oscillatory shear forces the hard beads into perfectly arranged stacks yielding strong structural colours. This technology allows for cheap production of such photonic films over kilometre scales. By varying the size of the starting nanospheres, different colours of light are reflected (Figure 1c), while stretching these elastic films reversibly changes their colour. Such chameleon materials could find their way into colour-changing wallpapers, or building coatings that reflect infrared thermal radiation.

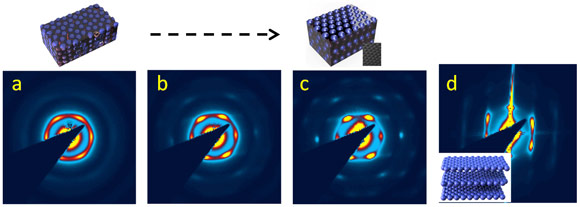

The 3D structure formation was studied destructively by scanning electron microscopy after slicing the samples by a focused ion beam. Going one step further, a non-destructive in situ study using small-angle X-ray scattering was performed at the Dutch-Belgian beamline BM26B (DUBBLE), where the setup allows an angular resolution better than 10 microradian to be achieved [1]. This was sufficient to clearly resolve the diffraction peaks at very small angles originating from the submicrometre periodicity in the sample, which is several thousand times larger than the X-ray wavelength. Moreover, the intrinsic width of the reflections could easily be resolved, which gave information on the development of the long-range periodic order in the sample.

Figure 2 shows examples of the data collected at BM26B. The patterns in panels (a) – (c) were taken in transmission at normal incidence for samples that had received different amounts of BIOS passes. The build-up of long-range order induced by the BIOS treatment is clearly visible. In Figure 2d, the diffraction pattern taken in the grazing incidence geometry is presented, which reveals the presence of stacking disorder between the layers.

During BIOS treatment multiple parameters such as shear stress, shear rate and the temperature were varied. The applied shear was either unidirectional or bidirectional with shear directions alternating by 30° between subsequent passes. The collected data along with theoretical modelling allowed us to identify the mechanism of the particle alignment, which provides a general principle of shear ordering in viscoelastic media that opens the way for the manufacture of other photonic materials.

Principal publication and authors

Large-scale ordering of nanoparticles using viscoelastic shear processing, Q. Zhao (a), C.E. Finlayson (b), D. Snoswell (c), A. Haines (a), C. Schäfer (d), P. Spahn (d), G.P. Hellmann (s), A.V. Petukhov(e,f), L. Herrmann (a), P. Burdet (a), P.A. Midgley (a), S. Butler (a), M. Mackley (a), Q. Guo (g) & J.J. Baumberg (a), Nature Communications 7, 11661 (2016); doi: 10.1038/ncomms11661.

(a) University of Cambridge (U.K.)

(b) Aberystwyth University (U.K.)

(c) Schlumberger Centre, Cambridge (U.K.)

(d) Deutches Kunstoff-Institut, Darmstadt (Germany)

(e) Utrecht University (the Netherlands)

(f) Eindhoven University of Technology (the Netherlands)

(g) Saga University (Japan)

References

[1] A.V. Petukhov, J.-M. Meijer, G.J. Vroege, Curr. Opin. Colloid Interf. Sci. 20, 272 (2015).

Top image: Iridescent flexible films of different colours are produced by changing the size of the starting nanospheres.