- Home

- News

- Spotlight on Science

- Machine learning...

Machine learning applied to X-ray tomography as a new tool to analyse the voids in RRP Nb3Sn wires

19-05-2021

Scientists have developed a new tool to investigate the internal features of Nb3Sn superconducting wires, combining X-ray tomographic data acquired at beamline ID19 with an unsupervised machine-learning algorithm. The method provides new insights for enhancing wire performance.

Share

Interest in niobium-tin (Nb3Sn) as a material for superconducting wires has recently been renewed because this material has been selected to replace niobium-titanium as the next step in accelerator magnet technology [1]. The design of these magnets relies on the availability of advanced Nb3Sn wires capable of withstanding extreme mechanical and thermal loads. The Restacked Rod Process (RRP) is considered the most promising technology to produce Nb3Sn wires at industrial scale for future accelerator magnets.

Nb3Sn is a brittle superconducting compound that cannot be drawn directly in the form of a wire. Instead, ductile precursor components are embedded in a copper matrix, drawn, brought to the final shape and then heat-treated, so that Nb3Sn forms in a reactive diffusion process. The result is a composite wire with several Nb3Sn sub-elements surrounded by copper. However, the diffusion process can lead to voids, which can play a role in the electro-mechanical and thermal behaviour of the wire. A team of scientists have developed a novel, non-destructive and non-invasive method to investigate the voids in high-performance RRP Nb3Sn superconducting wires, combining X-ray microtomography data at beamline ID19 with an unsupervised machine-learning algorithm, with a view to providing new insights into the development of these wires.

The new tool is ideal for characterising the distribution and morphology of the components of superconducting wires, with a particular focus on voids. The separation of the wire components (Nb3Sn sub-elements, copper matrix and voids) in the tomographic data was achieved using an unsupervised classification algorithm developed for clustering [2]. The underlying idea of clustering is to divide a given set of data into a specific number of groups based on certain patterns or similarities present in the data. In this case, it was adapted to recognise the different components of the wire and to provide their 3D reconstruction and the geometrical characterisation of the voids.

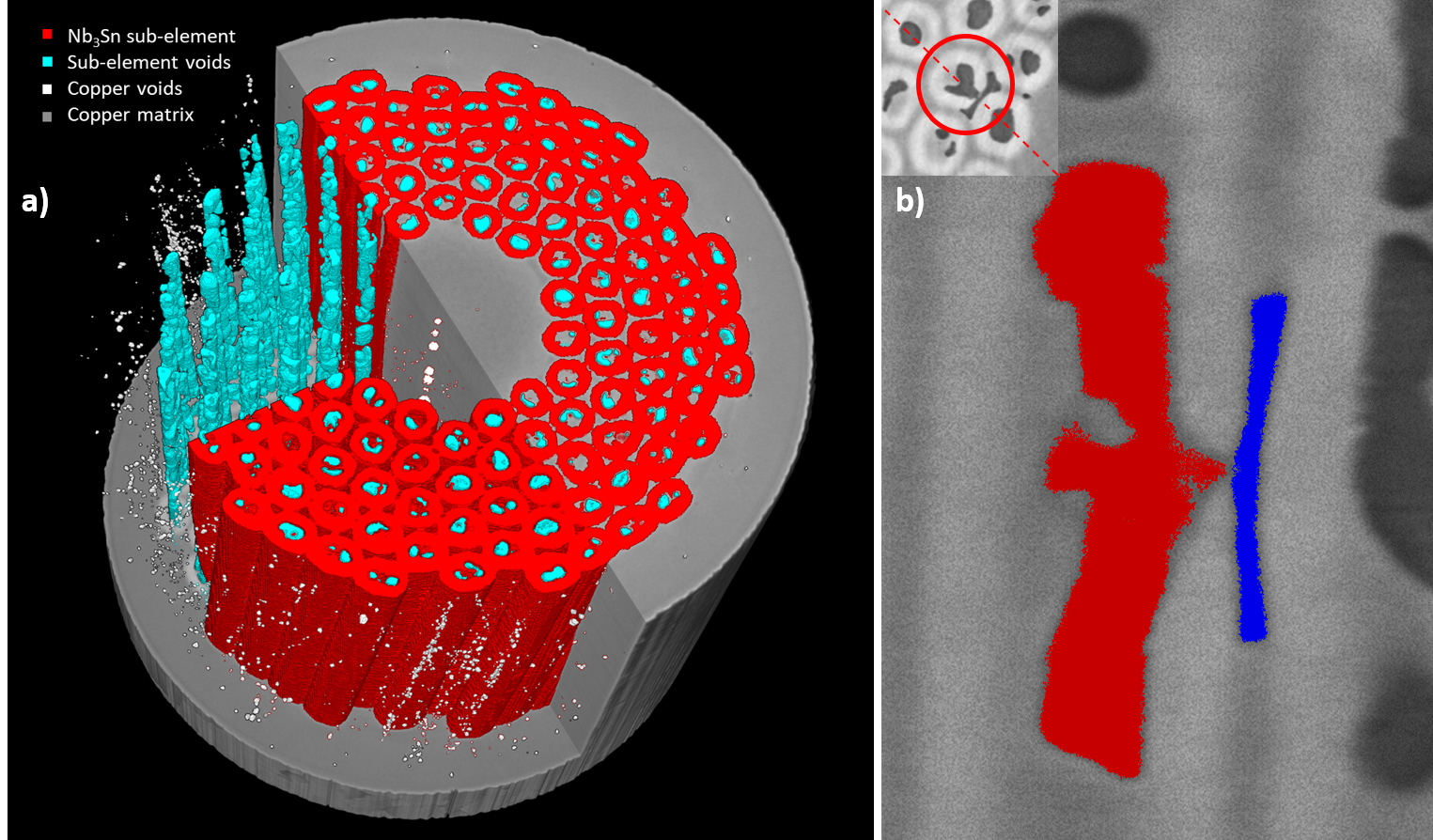

Fig. 1: a) 3D cross-section of a RRP Nb3Sn wire: Nb3Sn sub-elements (red), sub-element voids (light blue), copper voids (white), copper matrix (grey). b) Longitudinal cross-section of a void generated by Sn diffusion due to a leak in the sub-element. The void is highlighted in red inside the sub-element and in blue in the copper matrix, showing the sub-element failure point.

Two different types of voids can be detected in RRP Nb3Sn wires: one inside the copper matrix and the other inside the Nb3Sn sub-elements (Figure 1a). The former type can be related to Sn leaking from sub-elements and subsequent pollution of the copper matrix, which leads to poor electro-thermal stability of the whole wire. The tool was able to successfully locate the failure point in the sub-elements responsible for the Sn leakage (Figure 1b). The second type are Kirkendall voids, formed due to the diffusion of Sn in Nb during the wire heat treatment. They can be detrimental for the electro-mechanical performance of the wires as they act as stress concentrators, and superconducting wires experience large electromagnetic stresses in high field and high current conditions [3].

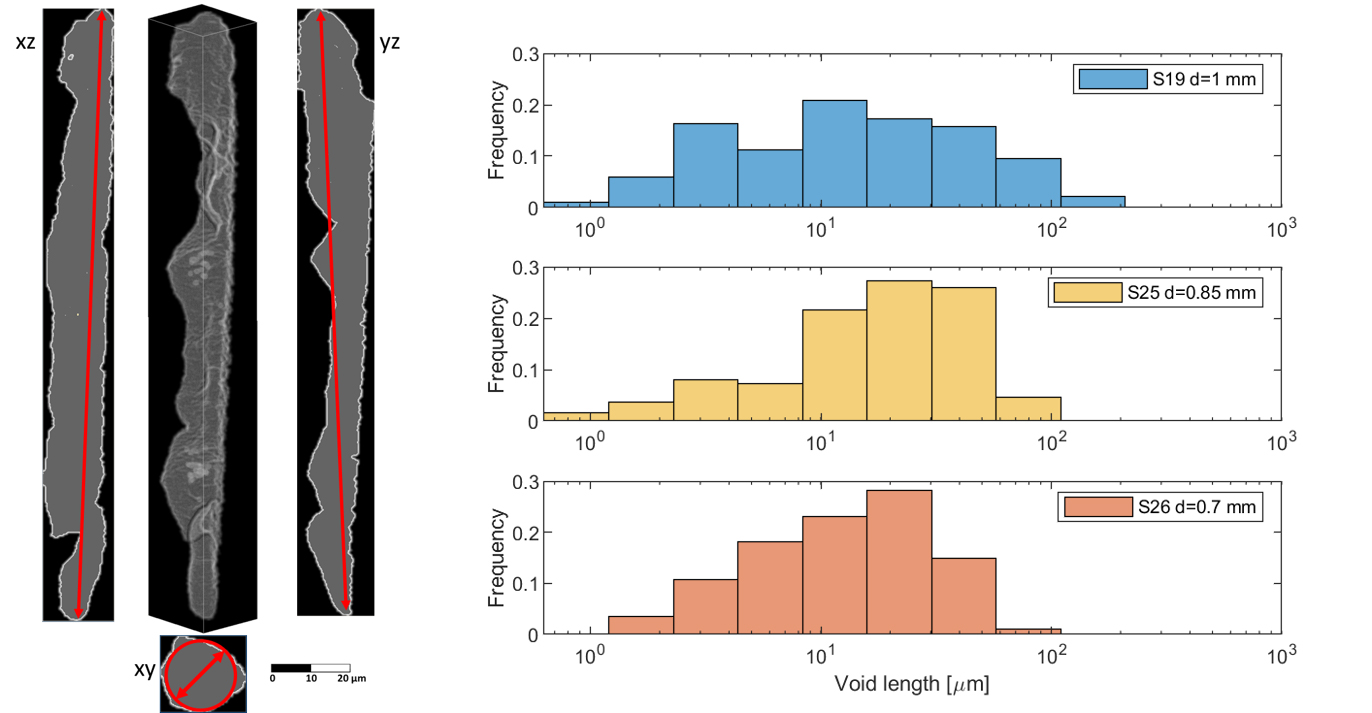

In particular, the new tool enables the development of tailored strategies to improve the tolerance to mechanical loads and thermal instabilities. Wires of different diameters (but the same design) were used to study void distribution and dimensions (Figure 2). The voids are morphologically similar, but the distribution of the void dimensions presents differences that make it impossible to directly rescale the electro-mechanical response for wires with identical layout but different diameter.

Fig. 2: Left: 3D reconstruction of a sub-element void. The projections of the void are shown in grey. The length of the voids is estimated using the major axes of the projections on XZ and YZ planes, while the void diameter was calculated from the circle equivalent to the projection on the plane XY. Right: Frequency of the sub-element voids as function of void length for the three analysed samples.

In conclusion, these analyses demonstrate the importance of accurate descriptions of the internal characteristics of the wire, and the effectiveness of advanced processing of the tomography data for a deeper correlation of the microstructure of Nb3Sn wires to their electro-mechanical and thermo-physical properties. Hence, this tool paves the way for novel wire design, assisted by detailed Finite Element Models (FEM) at sub-element level, with the final goal being further optimisation of wire properties relevant for use in future accelerator magnets.

Principal publication and authors

Machine learning applied to X-ray tomography as a new tool to analyze the voids in RRP Nb3Sn wires, T. Bagni (a), G. Bovone (a), A. Rack (b), D. Mauro (a), C. Barth (a), D. Matera (a), F. Buta (a), C. Senatore (a), Sci. Rep. 11, 7767 (2021); https://doi.org/10.1038/s41598-021-87475-6

(a) Department of Quantum Matter Physics, University of Geneva, Geneva (Switzerland)

(b) ESRF

References

[1] A. Abada et al., Eur. Phys. J. Spec. Top. 228, 755-1107 (2019).

[2] A.-N. Aimi Salihah, M. Yusoff & M. Zeehaida, WSEAS Trans. Biol. Biomed. 10 (2013).

[3] J.F. Troitino et al., Supercond. Sci. Technol. 34, 035008 (2021).