- Home

- Users & Science

- Scientific Documentation

- ESRF Highlights

- ESRF Highlights 2007

- Soft Condensed Matter

- Self-organisation during a drying process for porous grains

Self-organisation during a drying process for porous grains

The synthesis of ordered, homogeneous porous grains is an expanding area of materials research. One strategy for their formation is to dry the spray of a complex mixture containing nanoparticles and templating agents [1]. In this process, a continuous flow of micrometric droplets, made from the initial dilute solution, is dried along a hot tube in order to evaporate the solvent. Self-organisation of the constituents takes place during the evaporation. Organic moieties can even be removed via further calcination. The local structure of the final grains strongly depends on the initial compositions. Small-angle X-ray scattering can be used to investigate the ordered structural features of the final spray-dried grains at the nanometric scale [2]. However, the morphology of the grains at a larger scale depends critically on the kinetics of drying.

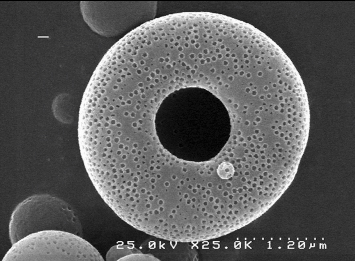

Two different regimes may be distinguished for the solvent evaporation from a complex nanoparticles solution confined in a droplet. Firstly, when the evaporation front moves faster than the time required for a particle to diffuse on the length scale of the drop, the grains may be heterogeneous. The final grains can be doughnut-like or even core-shell with an empty space inside, which has sometimes been observed by scanning electron microscopy (SEM). Secondly, when the drying is slower than the characteristic diffusion time of the nanoparticles, the evaporation occurs in a quasi equilibrium distribution of the nanoparticles inside the droplet and the formation of a dense spherical grain is anticipated.

For a solution containing a mixture of 5 nm silica nanoparticles with 50 nm polybromostyrene sulfonate we found that a large proportion of doughnuts were obtained, even when a slow evaporation rate was used (Peclet number Pe = ![]() dif/

dif/![]() evap = 0.01). One of the doughnuts is shown Figure 59. Together with the sphere-doughnut transition, the inner homogeneity of this type of material remains a crucial question for their further applications.

evap = 0.01). One of the doughnuts is shown Figure 59. Together with the sphere-doughnut transition, the inner homogeneity of this type of material remains a crucial question for their further applications.

|

|

Fig. 59: Example of a doughnut-like grain obtained upon drying a solution containing a mixture of 5 nm silica nanoparticles with 50 nm polybromostyrene sulfonate. The grain was observed before complete calcination. |

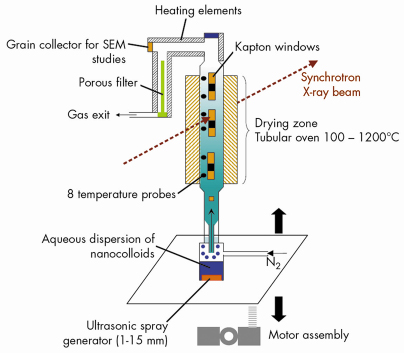

A complete measure of the structure by SAXS at the absolute scale is one way to obtain a quantitative investigation of the homogeneity. Moreover, the evaporation and the related organisation of nanoparticles can be probed in situ thanks to the high brilliance of the light source. Therefore our aim was to investigate the organisation at different scales during the complete drying sequence. Experiments were performed at beamline ID02, where a vertically mobile spray-drying system was set up (Figure 60). It allowed the whole process of grain drying and organisation to be traced directly inside the hot tube. A spray (![]() Droplets=0.07%) of very dilute (

Droplets=0.07%) of very dilute (![]() SiO2=2%) aqueous suspension of nanosilica (25 nm) was generated. After the evaporation profile reached equilibrium, the spray structure was scanned vertically along 50 cm of the tube (along which the temperature rose from 25°C to more than 100°C).

SiO2=2%) aqueous suspension of nanosilica (25 nm) was generated. After the evaporation profile reached equilibrium, the spray structure was scanned vertically along 50 cm of the tube (along which the temperature rose from 25°C to more than 100°C).

|

|

Fig. 60: Schematic representation of the spray dryer apparatus. The whole setup is displaced vertically through the beam to explore the temperature gradient. |

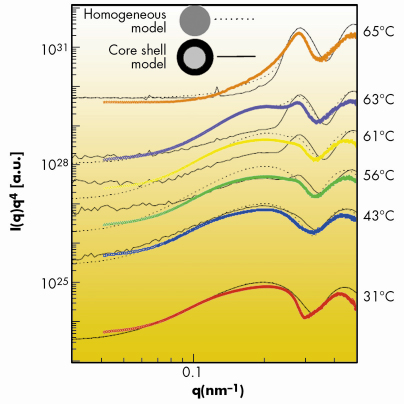

Figure 61 presents the evolution of I(q) when the system transforms from a dilute suspension of nanoparticles to densely-packed dried grains, the whole process occurring in 20 seconds.

From a quantitative model that takes into account the kinetics of evaporation inside the tube and the size distribution of the initial droplets in the spray, we are able to conclude that the compression is isotropic for the conditions (200-600°C) at which this spray system (and many others) usually work. Moreover, the occurrence of a layered morphology with a dense shell around a dilute core was invalidated since the quantitative variation of the scattering profile for such a case did not follow the experimental evolution of the scattering data (Figure 61) unlike the isotropic compression case as mentioned before. The source of the sphere-doughnut transition on a larger scale is yet to be found. However, slow drying does allow organised powders to be obtained, where pretty hexagonal organisation can be observed from the core to the surface of the grains [2].

|

|

Fig. 61: Porod plots of the scattered intensity at different heights in the drying tube (corresponding to increasing temperatures). The doted lines represent the fit by a model taking into account the slow evaporation of water from the droplets, allowing a full reconformation of the nanoparticles inside the wet droplets until completion of the drying process. |

References

[1] F. Iskandar, K. Mikrajuddin Okuyama, Nano Lett. 1, 231 (2001).

[2] D. Sen, O. Spalla, L. Belloni, T. Charpentier, A. Thill, Langmuir 22, 3798 (2006).

Principal publication and authors

D. Sen (a,b), O. Spalla (a), O. Taché (a), P. Haltebourg (a), A. Thill (a) Langmuir, 23, 4296 (2007).

(a) LIONS, CEA Saclay (France)

(b) Bhabha Atomic Research Center, Mumbai (India)