- Home

- Industry

- Industry news

- Towards uncoloured...

Towards uncoloured environmentally-friendly concrete

15-03-2017

ECOCEM, a company producing environmentally-friendly concrete, and academic collaborators have found the main cause for a blue tinge in its low environmental impact mortar.

Share

Company

ECOCEM, LMT (ENS Cachan, CNRS, Université Paris Saclay), LMDC (Université de Toulouse INSA/UPS Génie Civil).

ECOCEM Materials is the first independent producer of Ground Granulated Blast Furnace Slag (GGBS) in Europe. ECOCEM recycles a by-product from steel industry: granulated slag from a blast furnace which is in glassy form. The aim is to produce concrete with lower environmental impact: 1 ton of ground slag in the concrete industry avoids the emission of 750 kg of CO2 due to the production of Portland cement.

Challenge

In the quest for environmentally friendly materials, ECOCEM is using slag rich concrete, mortar and other materials. These materials might display a blue/green colour when they get consolidated. When the concrete is exposed to air, the blue/green colour turns to grey (in the case of cement concrete) or white (slag concrete). However, if the concrete is let to set for a long time in a form work or cured under water, it keeps the colour for up to its entire service life. This specific colour is concerning in applications where visual aesthetics are important. The origin of this blue/green tinge was not resolved until now, even if it has been attributed to the presence of polysulphur species in the slag, but without any scientific evidence.

Sample

- Ground granulated blast furnace slag (GGBS). It is an alumino-silicate glass containing in particular less than 1% of total sulphur species.

- Non-ground granulated slag collected from a steel factory without grinding.

- The last sample of slag was ground under nitrogen atmosphere in the laboratory to avoid sulphur oxidation.

|

|

A cafe built with ECOCEM cement. Credits: ECOCEM. |

Solution

In order to find out the origin of this coloration, scientists went to ID21 and used K-edge X-ray absorption near edge structure (XANES) spectroscopy to follow the evolution of the speciation of sulphur as the slag was hydrated.

The team used three methods to activate the slag: thermal, Portland cement and sodium silicate. First, they compared each method and then they compared the XANES results on blue and white samples and on zones that were not coloured.

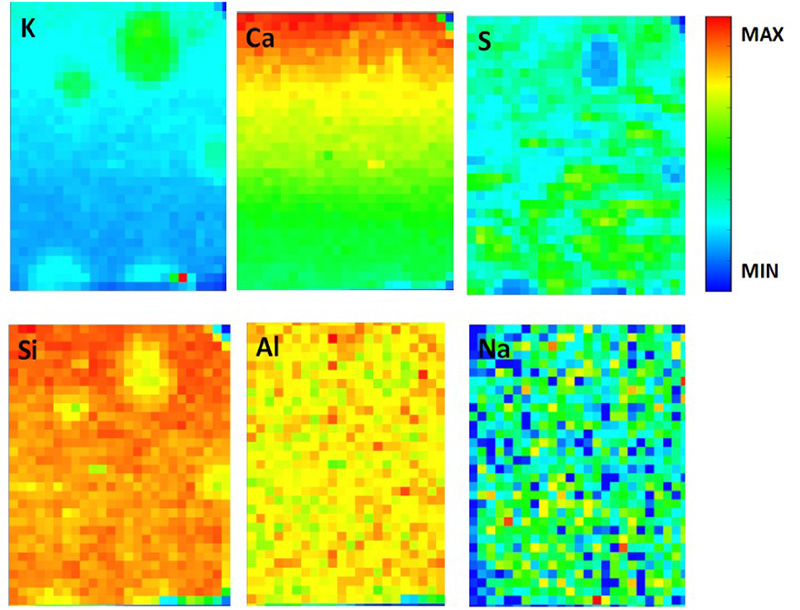

They found that, independently of the activating method, the blue colour was related to the presence of a pre-peak in the corresponding XANES spectrum. This did not happen anywhere else in the samples. They linked this pre-peak to the presence of the polysulphur radical anion S3- (as shown in the figure). This blue chromophore is known to be in particular at the origin of the deep blue of the stone lapis lazuli or the ultramarine pigment (derived from the Lazurite mineral).

As for each specific sample, the team found that the oxidation state of sulphur in a granulated slag obtained just after quenching was higher than in a ground slag or when ground under nitrogen atmosphere. This suggests that the superficial sulphur is oxidized under quenching.

Benefits

This research did not exclude the possibility of other elements influencing the coloration of slag-based concretes, in particular the presence of transition metals, but it showed clearly that the trisulphur radical anion is present and may play a major role.

In-depth understanding of the coloration mechanism was the key point if an effective decolorizing treatment was to be found. Through the study in ESRF by XANES, ECOCEM finally found an explanation of the blue/green colour: the presence of S3- in the concrete matrix. This study helped ECOCEM to explain clearly the reason of blue colour formation to their clients. And it also helped indirectly ECOCEM to find the solutions to eliminate the blue/green colour.

|

|

Elemental distribution obtained by μ-XRF with an exciting beam of 4040 eV for K and Ca, and 2480 eV for S, Si, Al, O and Na obtained by μ-XRF with an exciting beam, map size 2.6 x 3.5 mm2 with a step of 100 µm. |

This work was a collaboration of Laurent Frouint, ECOCEM Materials R&D director and Xiaoxiao Gao, ECOCEM Materials Research Scientist with Mohend Chaouche from ENS Cachan and Martin Cyr from INSA Toulouse and Marine Cotte from the ESRF.

Reference:

Top image: Portland cement (left) and ECOCEM cement. Credits: ECOCEM