- Home

- News

- Spotlight on Science

- Mechanical Behaviour...

Mechanical Behaviour of Wood Cell Wall Studied by in situ WAXS

09-12-2004

In situ X-ray scattering combined with tensile tests opens the way for analyses of the mechanical behaviour of complex hierarchical nano composite tissues.

Share

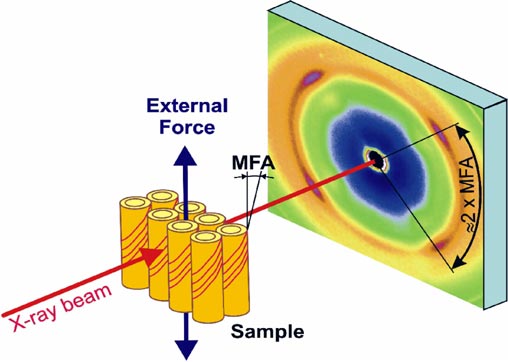

Wood is a complex organic material based on crystalline cellulose fibrils embedded in an amorphous matrix of lignin. In the tube-shaped wood cells, cellulose fibrils are wound in the form of a Z-Helix around the lumen. The tilt angle of the cellulose fibrils versus the longitudinal cell axis, usually called microfibril angle (MFA), predetermines the mechanical behaviour of the tissue (Figure 1) [1].

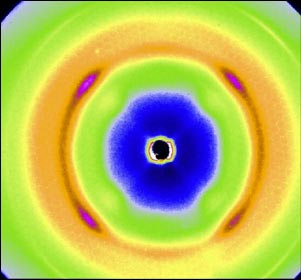

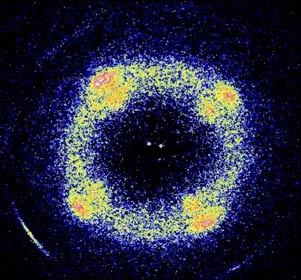

In situ wide-angle X-ray scattering (WAXS) on wood foils and on individual wood cells have been performed at beamlines ID01 and ID13, respectively (Figures 1,2). The tissues were stretched in tensile stages and the structural information was collected by a 2D detector using an acquisition time of 2 seconds (Figure 2). In the case of a single wood cell experiment, cells with length and diameter of about 1500 and 20 µm, respectively, were strained in a piezoelectric stage and investigated by a beam of 2 µm in diameter.

Fig. 1: Schematic description of in situ experiments at ID01 and ID13. Wood foils (and individual wood cells) were strained in a tensile stage and the structural data from the 2D detector were then correlated with the mechanical behaviour of the sample. MFA represents the tilt angle of the cellulose fibrils with respect to the longitudinal cell axis.

The in situ scattering experiments allowed the separation of deformation mechanisms inside the cell wall from those occurring between the cells. The data indicate that the magnitude of MFA decisively influences the mechanical response of the tissue in wet conditions and predefines the stress-strain behaviour. Moreover, a comparison of the results from foils and cells documents the presence of a molecular recovery mechanism in the cell wall which reforms the amorphous matrix between fibrils of crystalline cellulose. This mechanism of a "Velcro" type induces a re-stiffening of the cell wall during cyclic experiments and preserves the mechanical function of the tissue even at strain levels close to fracture [2].

References

[1] I.D. Cave, Wood Sci. Technol. 2, 268 (1968).

[2] J. Keckes et al., Nature Materials 2, 811 (2003).

Authors

J. Keckes (a), I. Burgert (b), M. Müller (c), K. Kölln (c), M. Hamilton (d), M. Burghammer (d), S.V. Roth (d), S.E. Stanzl-Tschegg (e) and P. Fratzl (b).

(a) Erich Schmid Institute for Materials Science, Leoben (Austria)

(b) Max-Planck-Institute of Colloids and Interfaces, Postdam (Germany)

(c) Institute for Experimental and Applied Physics, Kiel (Germany)

(d) ESRF

(e) Institute of Physics and Materials Science, BOKU, Vienna (Austria)