- Home

- Users & Science

- Scientific Documentation

- ESRF Highlights

- ESRF Highlights 2005

- Materials Science

- Observing Dislocation Structures Evolve During Annealing of Deformed Metals

Observing Dislocation Structures Evolve During Annealing of Deformed Metals

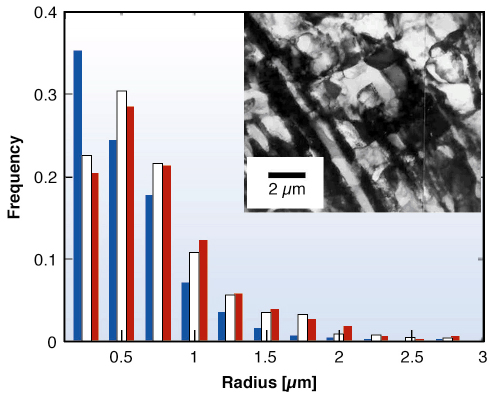

When metals or alloys are deformed plastically, line defects – dislocations – are introduced. The dislocations typically self-assemble into structures, where dislocation walls separate small dislocation-free crystals - the sub-grains (see inset in Figure 46). During subsequent annealing the stored energy in the structure is released by two processes: recovery (coarsening of the sub-grains) and recrystallisation (nucleation and growth of new grains) [1]. These processes govern basic properties such as hardness and ductility.

|

|

Fig. 46: Recovery of 38% cold-rolled Aluminium. Histograms of subgrain size (equivalent spherical radii) obtained from 500 diffraction spots in the as-deformed state (blue) and after 3 min (white) and 181 min (red) of in situ annealing at 300°C. Inset: Transmission Electron Micrograph of the as-deformed material. |

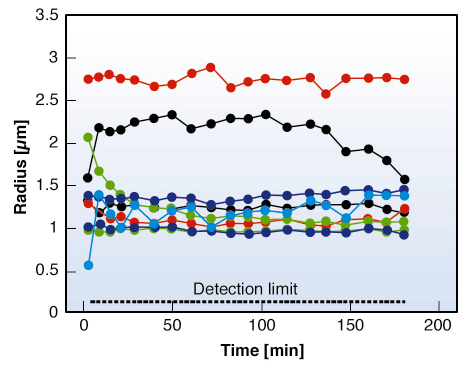

The 3DXRD microscope situated at beamline ID11 enables comprehensive 3D characterisation of the dynamics of grains within millimetre-thick polycrystalline specimens [2]. In this work the methodology is extended to the sub-micrometre scale for studies of sub-grains during recovery. The number of simultaneously illuminated sub-grains is reduced by focusing the beam to 7 x 7 µm2 and by studying a foil. (When the foil thickness is at least 10 times the sub-grain size, the sub-grains at the centre of the foil can be considered as representative of bulk.) In this way, distinct and non-overlapping diffraction spots from sub-grains as small as 70 nm can be observed. By monitoring the variation in position and intensity of any such spot, the evolution in orientation, strain, and volume of the sub-grain of origin can be inferred. Some results are shown in Figures 46 and 47.

|

|

Fig. 47: Recovery of 38% cold-rolled Aluminium at 300 °C. Growth curves for 9 selected sub-grains as function of annealing time. |

References

[1] E.g. F.J. Humphreys, M. Hatherley: Recrystallization and Related Annealing Phenomena, Pergamon Press, New York (1995).

[2] H.F. Poulsen: Three-dimensional X-ray Diffraction Microscopy, Springer, Berlin (2004).

Principal Publication and Authors

C. Gundlach (a), W. Pantleon (a), E.M. Lauridsen (a), L. Margulies (a,b), R.D. Doherty (c) and H.F. Poulsen (a), Scripta Mater., 50, 477-481 (2004).

(a) Centre for Fundamental Research: Metal Structures in Four Dimensions, Risø National Laboratory (Denmark)

(b) ESRF

(c) Drexel University, Department of Materials Science and Engineering (US)