- Home

- Users & Science

- Scientific Documentation

- ESRF Highlights

- ESRF Highlights 2011

- Soft condensed matter

- In situ observation of polymer-fullerene blend crystallisation for organic photovoltaics

In situ observation of polymer-fullerene blend crystallisation for organic photovoltaics

Polymer solar cells are very promising as light–weight and potentially low cost devices for solar energy conversion. Most polymer solar cells are based on the bulk heterojunction device structure, in which a polymer (donor) and a fullerene-derivative (acceptor) are deposited from a common solvent. As solvent evaporates, crystallisation and phase separation take place and give rise to an interpenetrating network of donor and acceptor materials. The energy conversion efficiency depends critically on the nanomorphology that develops dynamically during solidification of the wet film. Hence, there is need to gain knowledge of the phase behaviour and crystallisation of polymer/fullerene blends as basis for a rational search of material combinations and fabrication methods.

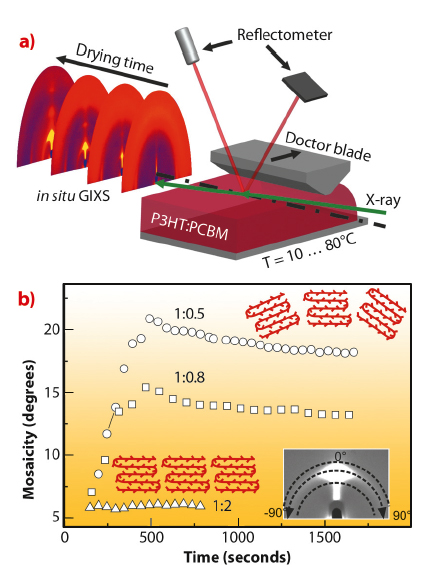

We have developed a novel setup at ID10B for the real-time observation of film crystallisation from solution. We obtained structural information by in situ grazing incidence X-ray scattering (GIXS) and monitored simultaneously the film thickness evolution by laser reflectometry as schematically depicted in Figure 60a. By this powerful approach we are able to investigate the dynamics of bulk heterojunction blend crystallisation in conjunction with the evolution of solvent fraction during film drying. We studied the well-known material combination of P3HT:PCBM dissolved in o-dichlorobenzene and probed the influence of parameters such as blending ratio [1] and drying conditions [2].

|

|

Fig. 60: a) Scheme of simultaneous in situ grazing-incidence X-ray scattering (GIXS) and optical reflectivity for film thickness monitoring of P3HT:PCBM films during solvent evaporation [1]. b) Time evolution of mosaicity for blends with P3HT:PCBM ratios 1:0.5 (circles), 1:0.8 (rectangles) and 1:2 (triangles) obtained from the P3HT (100) peak. The inset shows the azimuthal integration of the first order Bragg peak to calculate the mosaicity. |

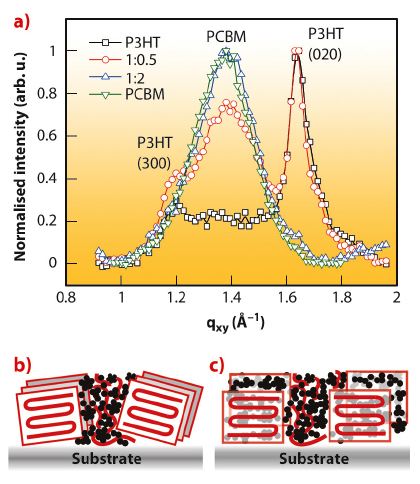

The GIXS real–time study presented here reveals a remarkable effect of the PCBM content in the development and evolution of P3HT ordering during blend drying. Figure 60b shows the time evolution of the mosaicity obtained from the (100) reflection which provides information about the orientation distribution of P3HT crystallites. For the P3HT:PCBM ratios of 1:0.5 and 1:0.8, the mosaicity increases considerably during the solvent evaporation, for the blend with highest PCBM content studied here, i.e. a P3HT:PCBM blend ratio of 1:2, the small angular distribution of the initially nucleated P3HT crystallites remains constant during crystallisation. We suggest that disorientation provides increased hole mobility perpendicular to the substrate as required for efficient solar cells [2]. Additionally GIXS reveals that PCBM hinders the development of P3HT interlayer π–π stacking for the P3HT:PCBM blend with 1:2 ratio (Figure 61). The lack of π–π packing is identified here a possible cause for the reported poorer power conversion efficiency for 1:2 blends.

|

|

Fig. 61: a) In–plane data obtained by GIXD using a point detector for the films. The in-plane (020) peak is related with the P3HT π-π-stacking, which is suppressed by an excessive amount of PCBM for 1:2 blending ratio. The structural characteristics of the dry films are schematically shown in b) for the P3HT:PCBM blending ratio of 1:0.5 and 1:0.8 and c) for the 1:2 blending ratio. |

This work increases the microscopic understanding of the structure formation during film drying influenced by the blend ratio and process conditions. This experimental strategy shows great potential for other solution-processed organic systems, such as organic light emitting diodes, organic thin film transistors or polymer membranes.

Principal publication and authors

M. Sanyal (a), B. Schmidt-Hansberg (b,g), M.F.G. Klein (c), C. Munuera (a), A. Vorobiev (d), A. Colsmann (c), P. Scharfer (b), U. Lemmer (c), W. Schabel (b), H. Dosch (e) and E. Barrena (a,f), Macromolecules 44, 3795–3800 (2011).

(a) Max Planck Institut für Metallforschung, Stuttgart (Germany)

(b) Institut für Thermische Verfahrenstechnik, Thin Film Technology, Karlsruhe Institute of Technology (Germany)

(c) Lichttechnisches Institut, Karlsruhe Institute of Technology (Germany)

(d) ESRF

(e) Deutsches Elektronen-Synchrotron (DESY), Hamburg (Germany)

(f) Institut de Ciencia de Materials de Barcelona, Bellaterra (Spain)

(g) Present address: Cavendish Laboratory, Department of Physics, University of Cambridge (UK)

References

[1] M. Sanyal, B. Schmidt-Hansberg, M.F.G. Klein, C. Munuera, A. Vorobiev, A. Colsmann, P. Scharfer, U. Lemmer, W. Schabel, H. Dosch and E. Barrena, Macromolecules 44, 3795–3800 (2011).

[2] M. Sanyal, B. Schmidt-Hansberg, M.F.G. Klein, A. Colsmann, C. Munuera, A. Vorobiev, U. Lemmer, W. Schabel, H. Dosch and E. Barrena, Adv. Energy Mater. 1, 363-367 (2011).