Diffractometer

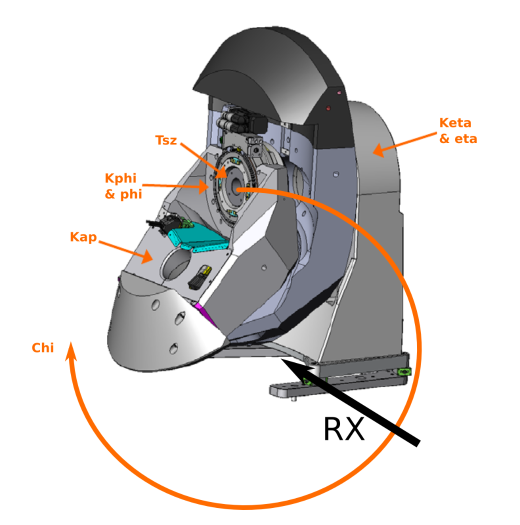

D2AM Kappa diffractometer

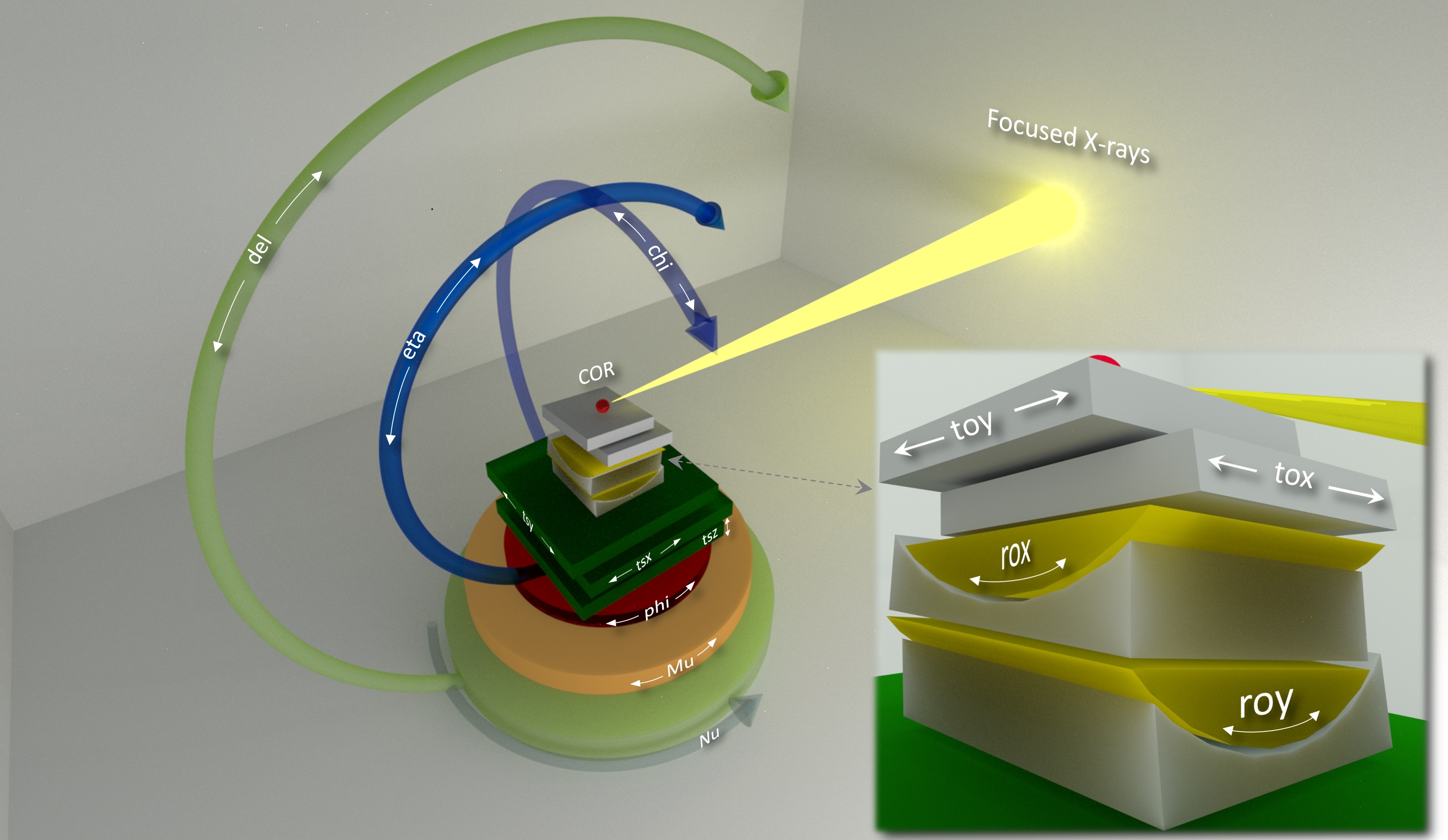

The KAPPA diffractometer for Materials Science is driven with the spec-kappa geometry. It leaves a large free space to adapt the sample environment. For the detection, vertical rotation axis NU and horizontal axis DELTA (-5°, + 130°) can carry an optional vertical analyzer. All the angular motions have a resolution lower than 0.001°, the confusion sphere being smaller than 0.06 mm. Using a Si (311) analyzer, FWHM less than 0.02° (2THETA) should be reached with powder samples. An optional goniometer-head (two translation on top of two cradles) is available on top of the kappa head for surfaces applications.

Two different hkl modes can be used: the 4-circles (kappa) and 6-circles (kappapsic) modes. It is used to define an orientation matrix by referencing two Bragg reflections, and thereafter perform hkl scans or access complex oriented Bragg reflections.

Specs and description of the diffractometer

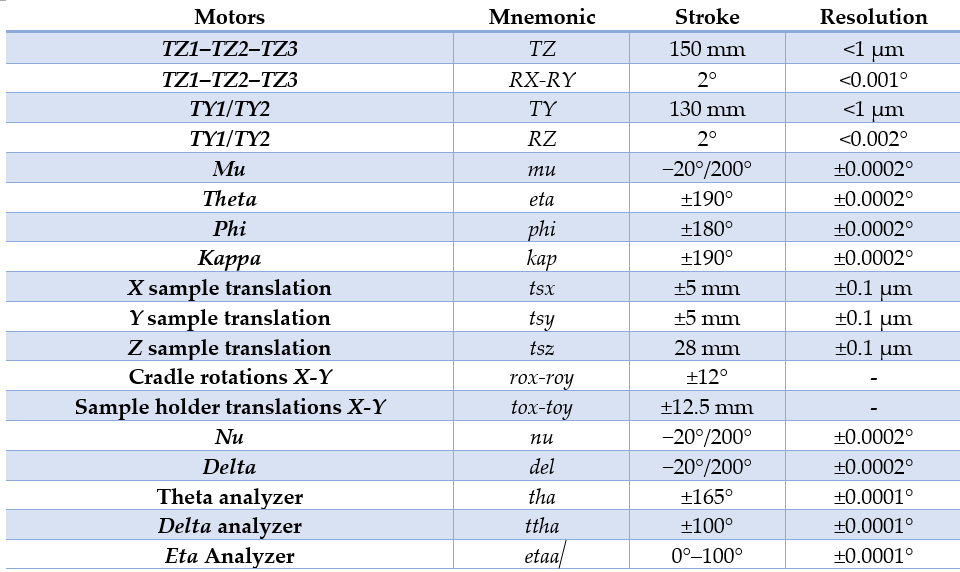

The D2AM diffractometer is a six-circle diffractometer with a kappa geometry from Newport. A list of its motors, their

respective mnemonics, strokes, and resolutions are provided in Table 1.

List of the KAPPA diffractometer motors

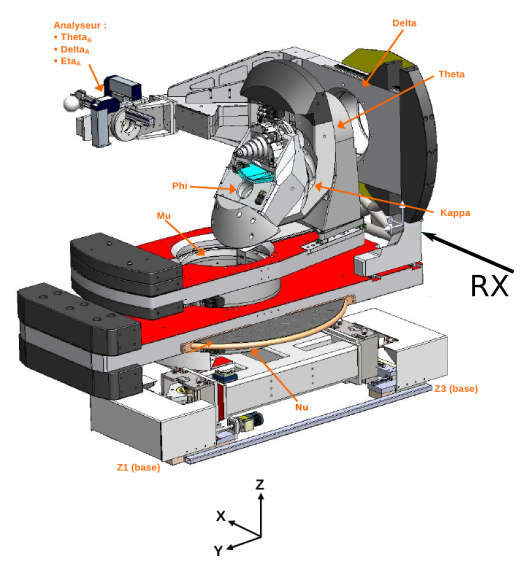

Tripod-Like encoded motors adjust the horizontality as well as the height of the diffractometer with respect to the X-ray beam. Two motors are dedicated for the translation perpendicularly to the X-ray beam’s direction and for the rotation around the z-axis.

A Mu base supports the kappa sample stage and can rotate around the Z-axis. The sample stage has three rotational motors: Theta, Kappa, and Phi. An XYZ encoded translation stage, on top of Phi, allows sample alignments. In addition, the diffractometer has a Chi rotation based on a combination of the three motors, Phi, Kappa, and Theta. This pseudo motor rotates the sample around the beam axis by maintaining the same incidence angle.

In summary, the sample can be oriented through 4 circles of the instrument which can be defined both as physical axis or virtual Eulerian ones:

- MU: sample rotation around a vertical axis (z).

- ETA - virtual eulerian angle: sample rotation around a horizontal axis perpendicular to the incident beam (y).

- CHI - virtual eulerian angle: sample rotation around x, it is carried by THETA. On figure 1 chi=90.

- PHI - virtual eulerian angle: sample rotation around the sample normal. It is carried by CHI and THETA so that the sample lies horizontal at chi=90 (its normal is z) and vertical at chi=0 (its normal is then y). Note that at CHI=0, ETA and PHI axis are parallel and horizontal.

- KETA: physical rotation associated with ETA

- KAPP: physical rotation around the Kappa axis.

- KPHI: physical rotation associated with PHI

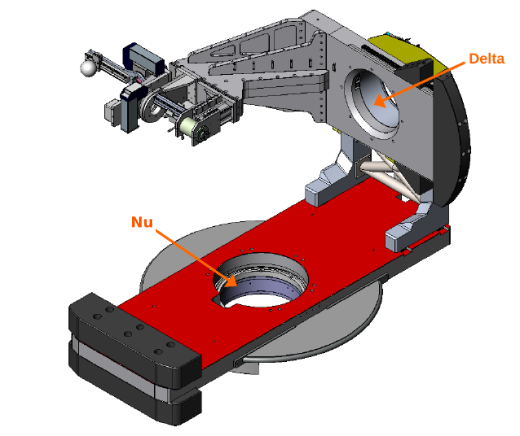

The detection section is equipped with a motorized arm with two rotations around the vertical z-axis and the horizontal y-axis:

- NU: a horizontal motion of the detector arm to allow measurement out of the polarization plane, its full use needs a special configuration of the experiment control program.

- DEL: a vertical motion of the detector arm. It is carried by NU.

This configuration gives access to a wide range of the scattering vector Q values.

-

Sphere of confusion: 60 µm for all combined rotations and 20 µm for phi

-

Maximum load on the sample stage: 20 kg

-

Maximum load on the detector arm: 50 kg

Three circles analyzer can be used

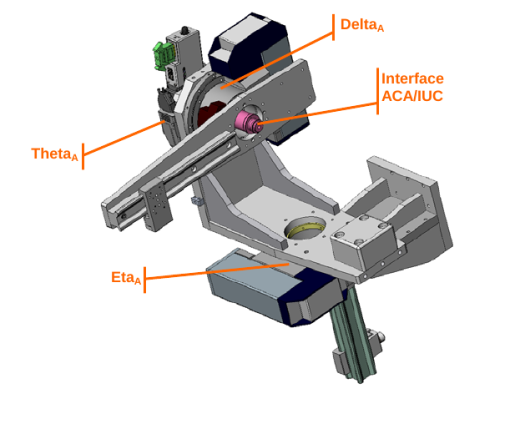

A 3-axis polarization analyzer system can be mounted on the detector arm consisting of:

two coaxial rotations: ThetaA for the crystal Bragg angle and DeltaA for the detection angle

A rotation (EtaA) that rotates the ensemble to swap between the two polarization configurations

Five analyzer crystals are available:

- a flat (8x8 mm)

- two curved Graphite (30x30x2 mm with 900 mm radius and 310 mm radius)

- two flat Si (30 x 10 x 2 mm, 50 x 20 x 2 mm)

For polarization analysis, crystals with a Bragg reflection close to 90 degrees are available depending on the working energy.

Phys. Rev. B 2018, 97, 085111

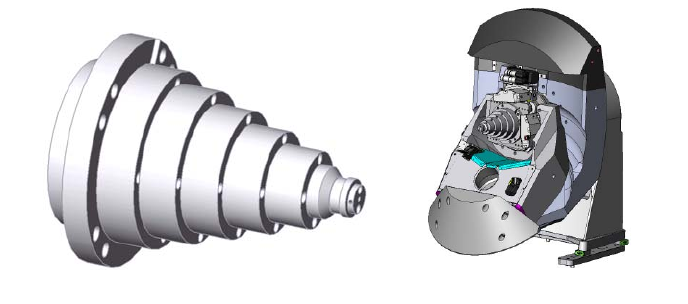

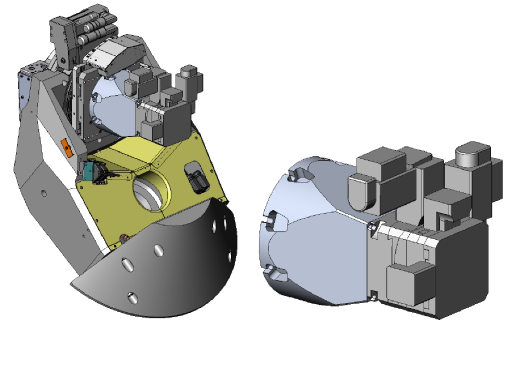

Motorized sample holder

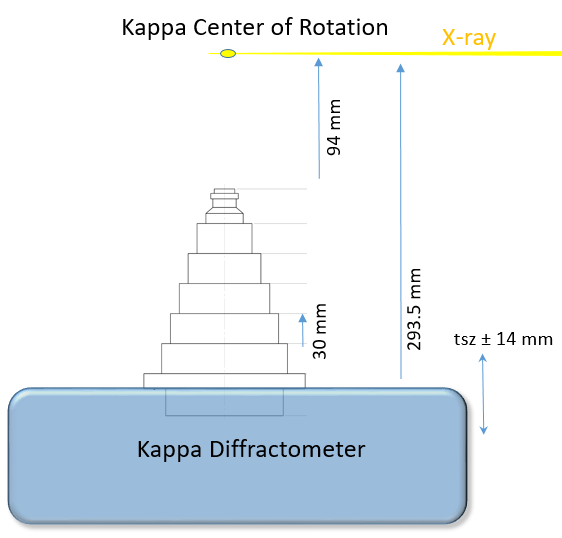

A simple x,y,z-motorized sample holder (tsx, tsy, tsz) can hold a wedding-cake-like structure. On top of it, a manually controlled small cradle system can be mounted.

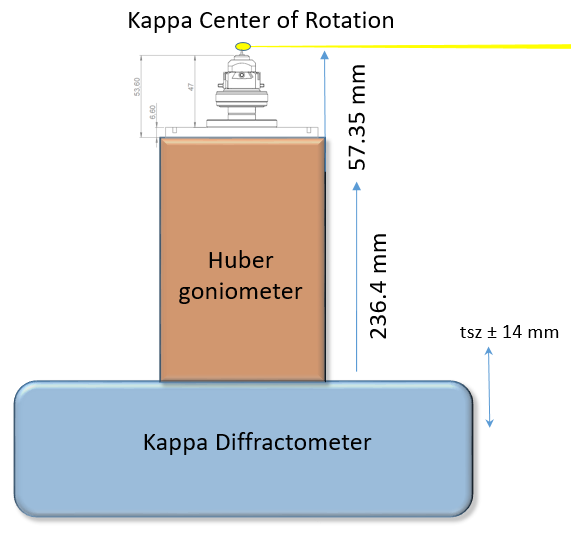

In addition, a heavy Huber goniometer head with two motorized, crossed cradles (Rox, Roy) and two translations (tox, toy) can be mounted on top of the kappa sample stage, i.e., on top of the theta, chi and phi motors. This configuration offers the possibility of aligning the sample surface, or diffracting planes with respect to the X-ray beam, to an accuracy of a few thousandths of a degree and, thereafter, to perform 3D-RSM under a constant incidence angle (the azimuthal angle). This can be done close to a given Bragg reflection or near the origin of reciprocal space (GISAXS experiments).

Confusion sphere less than 40 µm.

For specific questions not covered in this user guide, please email d2am.