- Home

- Users & Science

- Scientific Documentation

- ESRF Highlights

- ESRF Highlights 2014

- Status of the Upgrade Programme

Status of the Upgrade Programme

Following the occupation of the new buildings delivered within the EX2 project, 2014 has been the peak year for the implementation of the new beamline portfolio in the new premises. The year saw the inauguration of many new beamlines with unprecedented scientific capabilities, including ID02 (Figure 1), ID16A, ID16B, ID22, ID30A-1, and ID32. As we are entering the final year of Phase I of the Upgrade Programme, the construction of the new beamlines is approaching completion on time, within budget and in line with or exceeding specification.

|

|

Fig. 1: Inauguration of beamline ID02 (UPBL9A) at the 69th meeting of the Science Advisory Committee, November 2014. Pictured from left to right: F. Sette (Director General), Prof. K. Hämäläinen (Chairman SAC), N. Theyencheri (Scientist in charge of ID02), Dr A. Petukhov (SAC). |

The upgrade of the current accelerator complex is also heading towards its completion, with the latest step being preparation for top-up operation in the timing modes, scheduled for routine operation in 2016. Several tests on top-up operation during machine dedicated time have helped to identify the remaining issues and devise solutions. 2014 has also seen a large effort from all Divisions of the ESRF in the preparation of the Orange Book, with the proposal for the construction of a new low emittance storage ring light source at its core. Preliminary design work and cost estimates have been concluded successfully and led to the approval of the project by Council in June 2014. Representing our Users, we thank our staff for these achievements, delivered while the facility was kept in full user operation.

Upgrade of the source

2014 has seen the successful completion of several upgrades to subsections of the accelerator system.

The RF system has been renewed with the addition of solid state amplifiers and HOM-damped cavities. The manufacture of 12 additional cavities for Phase II is progressing well. All the planned straight sections have been lengthened from 5 m to 6 m, with one 7 m-long section in cell 23, enabling the installation of the RF cavities.

Following the construction of ID32, the new helical undulator will be put into place in the straight section in March 2015. Canted straight sections have been successfully installed, and only ID15 remains to be modified with this scheme, foreseen for 2015. An improved electron beam position monitoring system and a fast orbit feedback system have been successfully developed and installed.

The top-up project is progressing well, and several tests were carried out with beamlines in 2014. Feedback from the beamlines has been positive and, working with users, we have implemented improvements following their requests. The new bunch cleaning system installed in the booster this year will greatly aid top-up operation, scheduled for the beginning of 2016, once a formal agreement from the authorities has been accorded.

The technical design study for the UP Phase II, based on a hybrid 7-bend achromat lattice, has been completed and received very positive reports from the Accelerator Project Advisory Committee (APAC), the Scientific Advisory Committee (SAC) and the Administration and Finance Committee (AFC). In June 2014 it was submitted to the Council, which approved and launched the project. We entered the execution phase on 1st January 2015 with leaders being appointed for the Accelerator Project Office and Work Packages. The lattice and engineering designs have advanced well, with some magnets already at the prototype stage.

Renewal of beamlines

The Instrumentation Services and Development Division (ISDD) and the Experiments Division (ExpD), with the assistance of the Technical Infrastructure Division (TID), deliver new and refurbished beamlines. A significant number of beamlines are still under construction or will receive their finishing touches while they are already in user operation. A total of five beamlines are still under construction with most of them returning to user operation in 2015. Significant financial and human resources are also invested in the continuous refurbishment and further development of the remaining beamlines.

The main projects for beamline renewal are as follows:

UPBL1 – Diffraction for nano-analysis. Most of the optical components, including the white beam mirrors and multilayer monochromator, double crystal monochromator and transfocator have been assembled and installed. With the completion of the installation of the nano-diffractometer, the beamline received its first user team in December 2014. The SAXS/GISAXS end-station is in the assembly phase and will be commissioned early in 2015.

UPBL2 – High energies for interfaces and materials processing. The infrastructure for the beamline has been completed and first components installed in optics hutch OH1. The design, assembly and installation of the main optical components (transfocators, multilayer monochromator, double Laue monochromator) in OH2 is ongoing. The control infrastructure is under preparation. The large granite detector gantry has been installed and aligned.

UPBL4 – Nano-imaging and nano-analysis. The beamlines ID16A and ID16B have been installed and commissioned. Both beamlines resumed user operation in 2014 with some remaining work (cryo-cooling of the sample stage and high energy KB system (34 keV)) at the endstation of the ID16A-NI branch.

NI- nanotomography endstation: The installation of the endstation has been completed and the fixed-energy KB system (17 keV) commissioned. Most of the detectors are operational while the remaining cSAXS detector is still in the assembly phase. After reaching a beam size of 20 x 40 nm2 the beamline was successfully opened for user operation.

NA- nano-analysis endstation: The construction of the beamline was finished with all the detectors installed and the beamline has returned to user operation. The contaminated KB system, damaged by a defective gas line, will be replaced in 2015.

UPBL6 – Hard X-ray spectroscopy (RIXS & XRS). The horizontally deflecting (focusing) mirrors are operational and five APD detectors have been installed. The beamline returned to full user operation.

UPBL7 – Soft X-ray spectroscopy (RIXS & XMCD). All components for the beamline optics have been received and installed. Existing ID08 experimental facilities have been moved to the new ID32 premises in the experimental hall extension.

XMCD branch: The assembly of the XMCD branch including the new sample preparation facility has been finished and all components have been commissioned. First user experiments have been successfully performed with the XMCD setup as well as with a user-specific setup in the open access hutch attached to the XMCD branch.

All specifications have been met.

RIXS branch: The assembly of the 11m RIXS spectrometer arm is heading towards its final steps (Figure 2). All components have been received with only the gratings for the spectrometer still to be delivered.

|

|

Fig. 2: ID32 RIXS branch: refocusing optics, sample chamber, collimating optics and grating vessel (from right to left). |

UPBL9a – Time-resolved ultra-small-angle scattering. All optical components have been installed at beamline ID02 and the new 32 m long USAXS tube including the detector wagon has been assembled and aligned in the new premises (Figure 3). All SAXS (Figure 4) and WAXS detectors have been delivered and commissioned in the beam.

|

|

Fig. 3: ID02 detector wagon (front view) inside the USAXS tube. |

|

|

Fig. 4: Detectors inside the ID02 SAXS conveyor: FReLoN camera, beam viewer, Rayonix MX170 CCD detector, Pilatus 300K hybrid pixel array detector (from left to right). |

UPBL9b – Pump-probe and time-resolved experiments. The design of the new optical components for beamline ID09 has been finished and the orders placed. The high heatload chopper has been delivered and a new 3 kHz chopper is in the design stage. The beamline will remain fully operational throughout the upgrade.

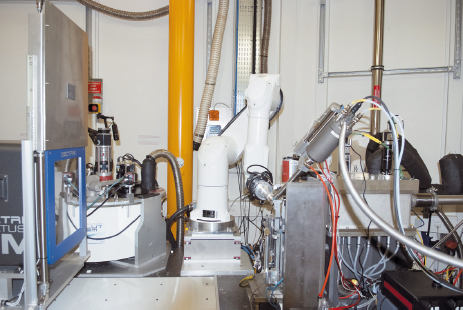

UPBL10 – Automated crystallographic evaluation. The new MASSIF sample handling facility including a high capacity dewar and RoboDiff setup (Figure 5) has been commissioned on ID30A-1 and has begun user operation. The microfocus beamline ID30A-3 has started user operation with a conventional experimental setup that will be replaced by a RoboDiff in 2015. The new Eiger 4M detector has been delivered and is being prepared for installation at the beamline. The installation of the new MAD beamline ID30B is in progress including the installation of a MD2S microdiffractometer, a new sample changer robot and a modified high capacity dewar (in collaboration with the EMBL Grenoble). The new Pilatus3 6M detector has been received and commissioned.

|

|

Fig. 5: Sample handling facility at ID30A-1 with high capacity dewar (left) and the new RoboDiff (centre) acting as sample changer and microdiffractometer. |

UPBL11 – Time-resolved and extreme conditions XAS. Work on several optical components continued while keeping the upgraded ID24 beamline fully operational. New detectors have been produced and are under commissioning.

ID22 – Powder diffraction. The installation of the new beamline optics and the transfer and refurbishment of the endstation have been completed. After a short shutdown of only four months the powder diffraction beamline successfully commenced user operation.

ID19 – X-ray imaging and palaeontology project. The upgrade and refurbishment of the beamline optics is nearly finished. The design, procurement and installation of detectors continues according to the TDR.

ID15 – High pressure, materials engineering, materials chemistry. The TDR for the two branches ID15A/B has been completed and approved. The optical design and configuration has been validated and the order for the construction of the new hutches was placed.

In the context of the Upgrade Programme, the ISDD continues to monitor its projects and associated resources, which are shared among several core activities, such as completion of the UP Phase I, daily operation of the facility and development of the in-house R&D programme for scientific instrumentation. In addition, in 2014, ISDD has focussed on defining a roadmap for UP Phase II, which includes strategic developments for future scientific instrumentation at the ESRF. This programme aims to provide engineering solutions for the best scientific exploitation of the new storage ring properties. The two main pillars of this programme are detector development and the implementation of a new model for data analysis. A special effort is foreseen to develop a new data analysis strategy and technical solutions to provide better service for ESRF users.

The year has also seen further consolidation of the project management organisation, with the implementation of an electronic system for project submission and associated approval workflow. This system is now used by both the Experiments Division and ISDD, and it is expected to be adopted by the ASD for the management of Phase II projects.

Several large-scale projects have also aimed to strengthen the ESRF’s capabilities in certain strategic areas. One such highlight is a new laboratory which will be entirely dedicated to the development and production of curved X-ray analyser crystals for spectroscopy applications. Similarly, 2014 has seen the implementation of a new Fizeau interferometer in vertical geometry with semi-automated stitching capability for optical metrology and the installation of a new system for cleaning carbonaceous contamination from optical surfaces.

In 2014, ISDD and ExpD initiated an in-depth review of double-crystal monochromator (DCM) technologies for spectroscopic applications. A dedicated working group is currently reflecting on the development of high-performance DCMs to cope with future scientific needs and also to anticipate the obsolescence of our aging DCMs.

As in previous years, special effort has been devoted to developing generic solutions and frameworks (see the chapter on Enabling Technologies). Alongside the complete specifications and initial design of a new DAnCE-based encoder processing unit, several software platforms have been further integrated and standardised, which include mxCuBE, LImA, PyFAI and PyMCA.

Detector R&D activities have continued to focus on the continuation or completion of several projects launched previously, including Medipix 3, HiZPAD2, XNAP and high efficiency scintillators, whilst reflection began for the Phase II development programme.

The instrumentation beamline, BM05, continued to be a strategic tool for instrumentation developments such as detector calibration, scintillator characterisation and testing of optical components. The beamline DCM has been upgraded and a new diffractometer will soon be implemented to better serve those instrumentation programmes.

Finally, commercial activities and new partnerships continued to support the European synchrotron community with the procurement of specific instruments such as a FReLoN-based detector and IcePAP controllers.

Moving on

The extensive UP Phase I building programme was completed in 2014 with the delivery of the EX2 extensions (ID16 satellite building, Belledonne Hall, Chartreuse Hall, Lab and Office Building) in parallel with the new site entrance and joint ESRF-ILL Science Building. The availability of the new premises has inevitably triggered the relocation of a large fraction of staff which will continue throughout 2015. From the outset, the ESRF was keen to embrace a high quality environment standard for the tertiary buildings, thus contributing to sustainable development and to provide a comfortable working environment for the support laboratories of the experimental programme.

The Lab and Office Building is now fully occupied and houses 30 laboratories for some of the beamlines and the ISDD. Some of these new laboratories were built to compensate for space forfeited to the beamline refurbishment programme, with beamlines now passing through the areas previously occupied by some of the laboratories and into the EX2 extension. Others have enabled activities to be re-grouped, such is the case for the Electronics Group, which in turn has freed up space in the Central Building. Laboratories are also being modernised and relocated around the experimental hall for an optimal operation in proximity to the new and refurbished beamlines.

The chemistry and surface science laboratories have moved from the Central Building to the Science Building. The space freed up in the Central Building will be converted into offices, allowing staff in dispersed groups to be brought together. This concerns the Software, Mechanical Engineering, Detector, and Alignment groups. At the end of this operation, more than 50% of the ESRF staff will have moved and will have gained improved working conditions and/or increased synergy to carry out the demanding work ahead to operate the facility and implement Phase II of the Upgrade Programme.

R. Dimper, P. Raimondi, H. Reichert and J. Susini