- Home

- Users & Science

- Scientific Documentation

- ESRF Highlights

- ESRF Highlights 2015

- Matter at extremes

- Nanosize effect on magnetism

Nanosize effect on magnetism

The nanosize effect of spherical templates to the evolution of magnetism in various thicknesses of iron film was investigated. The spatial distribution of magnetic moments was modelled and different magnetic evolution mechanisms were found depending on the sphere size. This led to the conclusion that the geometrical properties of the template play a fundamental role in the magnetic ordering which is crucial for industrial application.

Gordon E. Moore [1] predicted in 1965 that the number of transistors in an integrated circuit will double approximately every two years, which has proven to be valid for the past five decades. An analogous tendency was observed by Mark Kryder for magnetic disk storage density [2]. Based on the enormous increase of bit density in hard drives between 1990 and 2005, he assumed that the capacity of a 2.5” disk will reach 40 TBit/in2 by 2020. Unfortunately, 5 years before this date, the most enhanced magnetic hard disk had a factor of 30 less storage capacity. Several developments are now on the way, not only to reach, but maybe to pass 40 Tbit/in2.

In a conventional hard disk, the information is stored in collectively magnetised grains. There are two dilemmas about storage capacity increase. The magnetic grains are already so small, that further reduction would lead to the superparamagnetic effect, where the spontaneous magnetisation fluctuation would result in data loss. On the other hand, the magnetostatic and exchange interaction among the adjacent grains sets a limit on how “strong” the magnetisation should be in a grain without being perturbed by the vicinity.

A possible solution could rely on the information unit being bounded to a nanostructure, hence the strong exchange coupling within the particle, the shape anisotropy and the isolation of the particles would increase the energy barrier for thermal switching. This solution is called bit patterned media and was predicted to be eligible to store as much as 20 - 300 Tbit/in2 [3]. Although, this technique appears to be appropriate for future magnetic recording devices, it is well known that material properties may differ from bulk when entering the nanoscale regime and this is particularly true for magnetic materials. For this reason, scientists from all over the world are working to reveal the nanosize effects on magnetism. The Nuclear Resonance Beamline ID18 is also participating in this challenge. In the latest work, an ultrathin iron film was deposited on a flat silicon substrate as well as on 20 nm and 400 nm diameter silica spheres, and the effect of curvature and interparticle distances on the evolution of magnetism was studied. The thickness of the iron film was varied in the range where iron has a nonmagnetic/magnetic transition by gradual deposition, using molecular beam epitaxy under high vacuum conditions. To model the magnetic moment configurations in the iron cap, micromagnetic simulations based on the data obtained from in situ nuclear forward scattering (NFS), X-ray reflectivity, grazing-incidence small-angle X-ray scattering and ex situ atomic probe microscopy techniques were carried out.

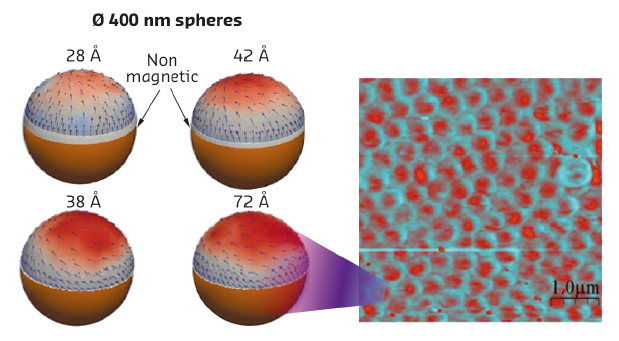

In the case of the 400 nm diameter spheres, the formed magnetic structure was determined by the topology of the spheres and the system could be considered as a sum of individual magnetic particles. At an iron thickness of 28 Å, the upper part of the sphere became magnetic, showing a spiral like (vortex) magnetic ordering on top and out of plane magnetisation at the side. The micromagnetic simulation of this magnetic moment configuration is shown in Figure 106. With increasing iron thickness, the out of plane component was gradually eliminated and replaced by a magnetic vortex (Figure 106).

|

|

Fig. 106: Magnetic moment configuration calculated by micromagnetic simulation for 28 Å, 38 Å, 42 Å and 72 Å- thick iron deposited on 400 nm diameter spheres (left) and the magnetic force microscopy image of the thickest iron layer (right). |

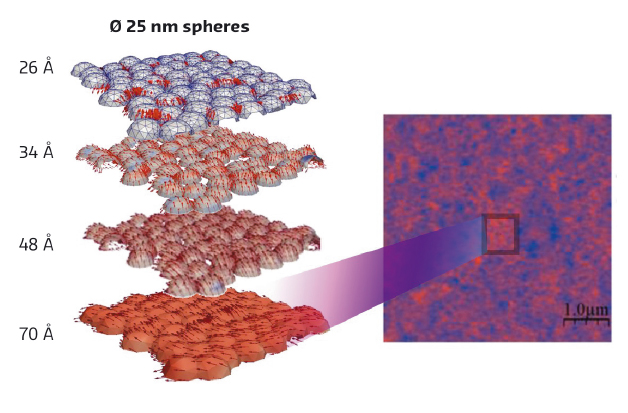

In contrast, for iron deposited on 25 nm diameter particles, iron became magnetic at a thickness of 26 Å in the contact region of the spheres and a uniformly distributed, well isolated magnetic structure was created (Figure 107). With further deposition, the whole layer became magnetic and a topology independent magnetic structure incorporating several particles with in plane magnetisation could be observed (Figure 107).

|

|

Fig. 107: Magnetic moment configuration calculated by micromagnetic simulation for 26 Å, 34 Å, 48 Å and 70 Å-thick iron deposited on 25 nm diameter spheres (left) and the magnetic force microscopy image of the thickest iron layer (right). |

Principal publication and authors

Evolution of magnetism on a curved nano-surface, D.G. Merkel (a,d), D. Bessas,(a), Z. Zolnai (b), R. Rüffer (a), A.I. Chumakov (a), H. Paddubrouskaya (c), C. Van Haesendonck (c), N. Nagy (b), A.L. Tóth (b) and A. Deák (b), Nanoscale 7, 12878-12887 (2015); doi: 10.1039/C5NR02928G.

(a) ESRF

(b) CER, Institute of Technical Physics and Materials Science, Budapest (Hungary)

(c) KU Leuven, Solid-State Physics and Magnetism Section, Leuven (Belgium)

(d) Wigner RCP, Institute for Particle and Nuclear Physics, , Budapest (Hungary)

References

[1] G.E. Moore, Electronics Magazine 38, 114 (1965).

[2] C. Walter, Scientific American, August (2005).

[3] R.A. Griffiths et al., J. Phys. D: Appl. Phys. 46, 503001 (2013).