- Home

- Users & Science

- Scientific Documentation

- ESRF Highlights

- ESRF Highlights 2017

- Status of the EBS

Status of the EBS

Three years into the EBS project, 2017 has seen the completion of many milestones, including the start of the assembly phase and the delivery of over 60% of the magnets. New flagship beamlines have been selected to take full advantage of the new source properties and upgrades are also underway.

Project overview

The past year marked the third year of the execution phase of the ESRF’s Extremely Brilliant Source (EBS) project, which will see the implementation of a new lattice for the storage ring. This will reduce the natural horizontal emittance from 4 nm to about 134 pm, thus greatly increasing the brilliance and coherence of the beam, opening up new perspectives for experiments that are not conceivable today. Much of the work of the project in 2017 concentrated on the delivery of the components and equipment, as well as the start of the assembly phase. A ‘mock-up’ of a standard cell to be used for the new machine was successfully completed, allowing corrections to be identified and integrated into the series production. In addition to this, great efforts went into the detailed planning and organisation of the dismantling and installation phases, complex work that defines the logistical requirements, task sequences and resource needs for the next three years. Finally, the EBS storage and assembly buildings were completed and started to be put to use at the end of the year as the project entered the assembly phase. This year has seen great progress for the EBS project, and preparations are well underway for the long shutdown in 2018.

The fifth and sixth MAC (Machine Advisory Committee) meetings were held at the ESRF in April and September 2017. Committee members from various institutes came together to discuss the recent progress of the EBS project and to make recommendations for the six months ahead. In September, the MAC was impressed with the solid progress made over the year and congratulated the ESRF staff on the completion of the mock-up cell as well as the ESRF 01 building, which was delivered on time and within budget.

Dipole assembly complete

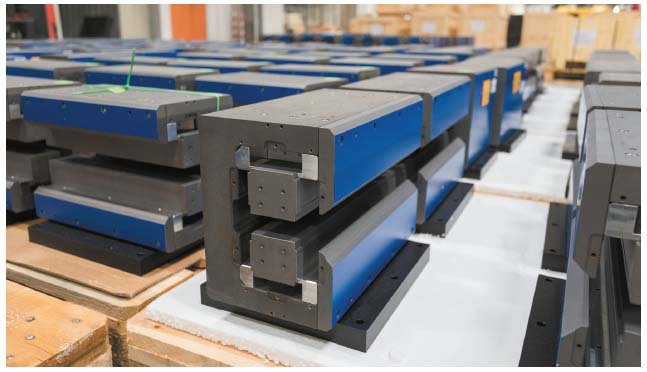

A project milestone was reached in 2017 with the completion of the assembly, measurement and fine-tuning of all 128 permanent magnet dipoles, which are to be installed in the EBS storage ring in 2018. Following tests on the first two dipoles, which were assembled and measured at the end of 2016, the series assembly and measurements started at the beginning of 2017. The maximum production rate was reached at the end of March and maintained until the end of production, in October. More than six tons of samarium-cobalt permanent magnet blocks have now been assembled in 640 magnet modules.

The dipole magnets are made of five modules (Figure 1) with fields ranging from 0.17 T up to 0.62 T; the resulting step function field profile will contribute to the low emittance of the new EBS machine. The dipoles with longitudinal gradient (DL) were good candidates for the ESRF’s well established permanent magnet technology. The permanent magnet DLs are very compact due to the absence of coils; complex coils would be needed for generating field steps along the magnet. Their zero electrical consumption, combined with the absence of power supplies and water cooling, will result in significant energy savings.

|

|

Fig. 1: Each permanent magnet module (above) weighs about 80kg and five modules are needed to make up each of the 128 complete dipoles. |

The assembly and measurement of the DLs consist of several steps. Permanent magnet blocks are first inserted into the iron yokes of the magnet modules, before measuring and trimming the field of the individual magnet modules. The modules are then assembled together to build a complete DL; the field of the complete DL is measured and the angle and trajectory offsets it gives to the electron beam are trimmed. The magnet then undergoes fiducialisation, i.e. measuring the coordinate of survey reference with respect to the magnetic centre. Finally, the DL is installed on its final support and stored, ready to be mounted onto the girders during the assembly phase.

Mock-up completed

Another major milestone was reached in September 2017; the successful completion of a mock-up of a standard cell to be used for the new machine (Figure 2). All magnets are now installed and aligned, all vacuum chambers have been connected together and inserted into the magnets, including front end vacuum lines, and put under vacuum. The mock-up assembly allowed staff to identify many necessary corrections, which have been integrated into the series production.

|

|

Fig. 2: The completed ‘mock-up’ of an EBS cell in the Chartreuse Hall. |

New buildings for EBS

Significant building work has taken place over 2017, and three buildings for use in the EBS project are now up and running. The beginning of June saw the mounting of buildings ESRF 02 A and B, which are now fully operational. Components for the EBS are to be stored in these two buildings before being transferred to ESRF 01 for assembly. In early September, ESRF 01, which is to be used for the assembly phase of the EBS project, was completed and inaugurated (Figure 3).

|

|

Fig. 3: The inauguration of ESRF 01 on 14th September. From left: Francesco Sette (ESRF Director General), Richard Walker (Chairman of the MAC), Thierry Marchial (Head of Buildings and Infrastructure), Sylvie Campillo (architect) and Dieter Einfeld (accelerator physicist). |

Start of the assembly phase

Following the delivery of the ESRF 01 assembly building in September 2017, the assembly phase of the EBS project has begun. This period, lasting from November 2017 to the end of 2018, will see 128 girders mounted with state-of-the-art magnets, vacuum chambers and instrumentation, ready to be installed in the storage ring tunnel in early 2019.

The work takes place on three assembly lines (Figure 4), each one dedicated to a specific task; mounting and aligning the magnets, placing the vacuum chambers inside the magnets, and finally closing the magnets for final precise alignment. Each process lasts around a week then the finished girders are placed in storage, awaiting the installation phase. Several girders have already been equipped with magnets and vacuum chambers.

|

|

Fig. 4: The assembly line in ESRF 01. The assembly team is being supplemented by magnet and vacuum specialists from Budker Institute of Nuclear Physics, Russia. |

RF cavities conditioned

In preparation for installation into the EBS machine in 2018, all 12 HOM-damped cavities have now been delivered and successfully RF conditioned to 750 kV (Figure 5).

|

|

Fig. 5: The RF-conditioned cavities are stored in a dedicated zone in the ESRF experimental hall. |

The manufacturing of the HOM absorbers is progressing well. The challenging brazing of the absorbing ferrite plates is being followed up very carefully by means of sophisticated qualification procedures involving ultrasonic and RF power tests. The HOM absorbers are expected to be delivered during 2018 and then installed.

The additional RF waveguides needed to power these cavities from the existing RF transmitters were ordered last October and will be delivered before June 2018. The upgrade of the klystron transmitters, including a refurbishment of the local control, is also progressing according to schedule.

Powering the EBS magnets

Several large magnet powering contracts were signed in 2017, following the finalisation of the power requirements for the EBS storage ring and the launch of the procurement of more than 2100 power supplies to power the main and corrector EBS magnets. The prototypes for the main coil power converters have shown an efficiency close to the calculated values. The optimised magnets and power supply design will result in 40% overall reduction of energy consumption for the magnetic elements. The highly optimised voltage DC cabling distribution around the technical gallery is progressing well and the first test of the common sources was promising. The challenge of testing the magnetic field polarities is under preparation for smooth commissioning of the future beam.

Human resources for the long shutdown

Planning is underway to pull together the large workforce required for the dismantling and installation phases of the long shutdown in 2019. There will be a high demand for human resources during these phases and, at times, more than 100 persons will be working in different areas in the accelerator tunnel and the technical zones. It is foreseen that staff currently working on the beamlines will help with these activities and organisation charts have already been drawn up such that all roles are well attributed in advance.

Public beamline upgrade

Following the extraction of eight proposals for new beamlines within the EBS from 48 expressions of interest in 2017, eight Conceptual Design Reports (CDRs) were prepared:

• CDR1 – Beamline for coherence applications

• CDR2 – Beamline for hard X-ray diffraction microscopy

• CDR3 – High throughput large field phase-contrast tomography beamline

• CDR4 – Surface science beamline

• CDR5 – High-flux nano-X-ray diffraction beamline for science under extreme conditions

• CDR6 – Facility for dynamic compression studies

• CDR7 – High brilliance XAS beamline

• CDR8 – Serial crystallography beamline

After evaluation the ESRF SAC recommended to accept four CDRs for construction within the EBS (EBSL1 – CDR1, EBSL2 – CDR2, EBSL3 – CDR3, EBSL8 – CDR8), which was endorsed by Council at its meeting in June 2017. In addition, the SAC recommended to implement as many as possible of the remaining four CDRs within the regular beamline refurbishment programme (CDR4, CDR5, CDR6, CDR7). Based on this recommendation, a timetable for the construction of beamlines and refurbishment has been worked out for the period 2018-2022. Planning and design works have already started for the two flagship projects, EBSL3 and EBSL8, which will be constructed on the ports BM18 and ID29, respectively.

In parallel to the development of the EBS upgrade beamline portfolio, regular works continued to prepare the existing beamline portfolio for the new source. The refurbishment of the MX microbeam beamline ID23-2 was finished and the beamline resumed full user operation. The refurbishment of the X-ray microscopy beamline ID21 continues and is on schedule. The beamline will host the new high performance prototype scanning double crystal monochromator (DCM), which is progressing on schedule as well.

Progress has also been achieved on the two user platforms, the high power laser facility (HPLF-I) and the cryo-electron microscope (cryo-EM). The order for the high power laser has been placed and the planning for the modification of the infrastructure on beamline ID24 for the laser installation has started. The cryo-EM has been delivered and commissioned in the newly constructed premises in the Belledonne Hall between beamlines ID01 and ID02. The cryo-EM has been in full user operation since November 2017.

CRG beamline upgrade

The transfer of beamline BM14 to the DUBBLE consortium and preparations for the construction of a new beamline on port BM07 for the transfer of the French CRG beamline BM30A-FIP are progressing as planned. Work on the beamlines BM20 and BM28 in preparation for the new source continues on schedule as well.

Instrumentation and data management

The EBS project comprises an ambitious instrumentation and technology programme, which is required to gain the greatest benefit from the new source properties. In 2017 there was significant progress in data management and analysis. Version 0.6.0 of the silx toolkit (https://github.com/silx-kit), a library of common software routines for analysing data from synchrotron sources, was recently released. It includes many new features such as support for OpenGL for high speed graphics. Metadata collection is implemented on 11 beamlines and is in progress on a further six (refer to http://www.esrf.fr/datapolicy for the list of beamlines), and work has started on the long-term data archiving for 10 years, as part of the plans to complete the implementation of the ESRF data policy by 2020. A dedicated high-speed disk storage system of 2 petabytes has been purchased and is now operational for the images generated by the new cryo-EM platform.

The rotary axis of the prototype double-crystal monochromator (DCM) was assembled and is currently undergoing tests in the laboratory. In parallel, work for its implementation on ID21 is in progress and all efforts focus on installing the DCM on ID21 by the summer of 2018.

The Detector Development Plan is shaping up, with the establishment of strategic partnerships for the development of new sensor materials.

In order to strengthen expertise in mechatronics, which integrates online measurements for correction of position errors and advanced control strategies, a mechatronics task force has been created to foster synergies between the ISDD groups and provide a platform for the exchange of experience. Investments in real-time control hard- and software were made and the creation of a mechatronics laboratory is underway.

In the domain of optics and metrology, novel refractive X-ray lens optics were developed and characterised, and a new surface metrology prototype instrument based upon Shack-Hartmann sensor technology was installed and commissioned.

R. Dimper, M. Krisch, P. Raimondi, H. Reichert and J. Susini