- Home

- Users & Science

- Scientific Documentation

- ESRF Highlights

- ESRF Highlights 2017

- Structure of materials

- High-speed imaging of thermal runaway in Li-ion batteries

High-speed imaging of thermal runaway in Li-ion batteries

Li-ion batteries have universal applications, from medical implants to grid-scale energy storage. Thermal runaway within Li-ion cells poses significant safety risks but the process is challenging to characterise. An internal short circuiting device is used in conjunction with high-speed radiography to initiate thermal runaway and record propagation through the cell to evaluate the safety of cell designs.

The use of high energy-density Li-ion batteries is ubiquitous, from powering portable electronics to providing grid-scale storage, but Li-ion batteries can and do fail, sometimes catastrophically. Although rare, recent high-profile cases of catastrophic failure highlight the importance of understanding battery failure and improving their safety; for example, the recall of Samsung’s Galaxy Note 7 smartphones and the grounding of the Boeing Dreamliner aircraft fleet.

Manufacturing defects and abnormal operating conditions can lead to internal short circuits in commercial Li-ion batteries, which can, in worst-case scenarios, generate enough heat to initiate a cascade of exothermic reactions in a process known as ‘thermal runaway’. Internal short circuiting is of particular interest as it is thought to be responsible for a number of high-profile, real-world failures.

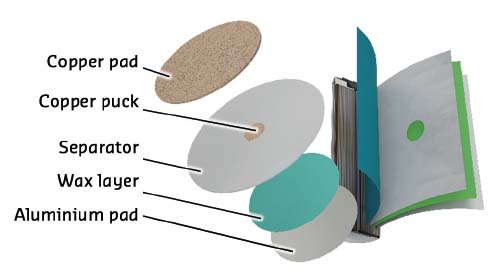

As highlighted in a previous study [1], it is very difficult to predict when and where thermal runaway will occur due to the extreme speed of failure and uncertainty surrounding the location of initiation, making the process extremely difficult to observe and characterise. To circumvent this challenge, a device capable of generating an internal short circuit (ISC) on-demand and at a pre-determined location in Li-ion batteries was used to induce thermal runaway (Figure 135) [2]. The temperature-activated ISC device, developed by NASA and NREL [3], mimics hidden defects that can occur during battery manufacturing. Knowing when and where the cell will fail allowed characterisation of the phenomena that occur during catastrophic failure using high-speed X-ray imaging at beamline ID19.

|

|

Fig. 135: Internal short-circuiting device. |

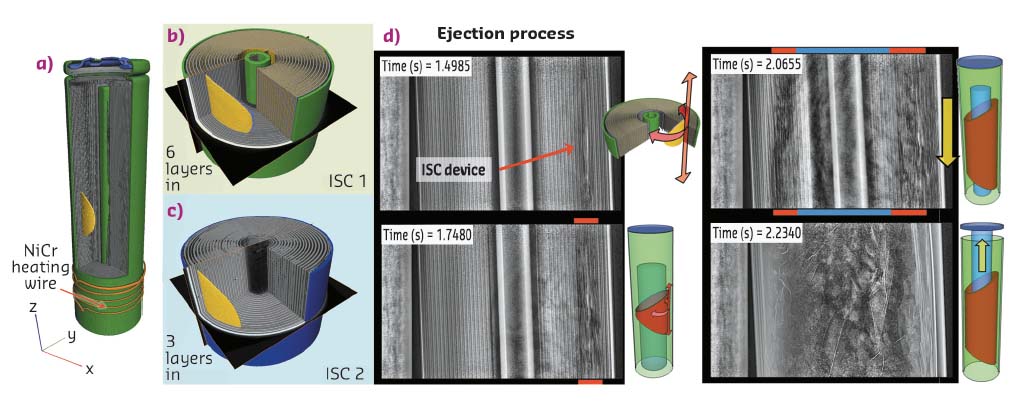

The ISC device was inserted at different locations within 18650 cells (Figure 136a-c) to gain insight into cell design vulnerabilities with respect to the location at which thermal runaway initiates, e.g. an increased risk of undergoing side-wall rupturing or bursting. For the first time, the mechanism through which a short-circuit failure initiates and propagates thermal runaway inside a cell was captured in real time (Figure 136d). At ID19, high-speed X-ray imaging at 2000 fps revealed how thermal runaway spreads via a characteristic cylindrically shaped reaction zone (Figure 136d), where the decomposition reactions propagated fastest in the longitudinal and circumferential directions. This evolution of the reaction zone resulted in an intact core becoming surrounded by a fluidised region, reducing the shear stress on the intact electrode assembly and contributing to it shifting towards and clogging the vent, causing the cell to burst.

|

|

Fig. 136: a-c) Locations at which the ISC device was placed inside 18650 cells. d) Process of initiation and propagation of thermal runaway. |

The ability to control the location of initiation also allowed examination of whether cells are at greater risk of undergoing side-wall rupture when thermal runaway initiates closer to the surface of the cell casing. X-ray images showed that when thermal runaway is initiated three layers deep into the cell, as opposed to six layers deep, its reaction front reaches the casing of the cell in less than 1/10th of the time. This has implications for early temperature-induced weakening of the steel casing and the formation of more favourable conditions for side-wall rupture to occur.

The results of this work demonstrate the utility of combining high-speed X-ray imaging with selective triggering of thermal runaway within similar commercial cells. By linking internal structural dynamics with external observations and thermal measurements, risks can be characterised with new insight into the internal behaviour of cells. Failure mechanisms such as cell bursting, sidewall rupture, or contained thermal runaway each pose different risks, and mechanical design of cells and their tendency to undergo such failures should be considered when assessing their suitability for powering systems. The insights achieved from high-speed X-ray imaging at ID19 provide important information for validation of thermal runaway models as well as for informed design of next-generation lithium-ion batteries.

Principal publication and authors

Characterising thermal runaway within lithium-ion cells by inducing and monitoring internal short circuits, D. P. Finegan (a), E. Darcy (b), M. Keyser (c), B. Tjaden (a), T. M. M. Heenan (a), R. Jervis (a), J. J. Bailey (a), R. Malik (d), N. T. Vo (e), O. V. Magdysyuk (e), R. Atwood (e), M. Drakopoulos (e), M. DiMichiel (f), A. Rack (f), G. Hinds (g), D. J. L. Brett (a) and P. R. Shearing (a), Energy Environ. Sci. 10, 1377-1388 (2017); doi: 10.1039/c7ee00385d.

(a) Electrochemical Innovation Lab, Department of Chemical Engineering, University College London, London, (UK)

(b) NASA-Johnson Space Center, Houston, Texas (USA)

(c) National Renewable Energy Laboratory, Golden, Colorado (USA)

(d) Warwick Manufacturing Group, University of Warwick, Coventry (UK)

Diamond Light Source, The Harwell Science and Innovation Campus, Didcot (UK)

(e) ESRF

(f) National Physical Laboratory, Hampton Road, Teddington (UK)

References

[1] D. P. Finegan et al., Nat Commun. 6 (2015).

[2] D. P. Finegan et al., Energy Environ. Sci. 10, 1377 (2017).

[3] M. Keyser et al., U.S. patent 9142829B2 (2015).