X-ray mirrors with sub-nanometre height errors achieved

Modern synchrotron beamlines require optical components of superior quality to accurately focus the X-ray beam on the sample. The ESRF’s X-ray Optics group has succeeded in reducing the surface errors of a 300 mm-long flat silicon (Si) X-ray mirror down to the sub-nanometre level using a differential deposition technique, which compensates for irregular surface topography.

Share

With many synchrotron facilities planning or already upgrading to fourth-generation sources, the requirements regarding the surface roughness of optical components are becoming more stringent. In the case of X-ray mirrors, the surface height errors, i.e., the difference between the real topography and a perfect surface, must be kept to a minimum to avoid parasitic light scattering.

Different strategies to reduce the surface height errors have been developed, which are grouped into two main categories: subtractive and additive methods. The former ones rely on locally removing material from the surface, as is the case for ion-beam figuring, for instance. Within the latter approaches, a possibility is to add a variable-thickness coating on the surface to compensate for the uneven topography.

One way to apply such a coating is differential deposition. This technique is implemented at the ESRF using magnetron sputtering on a Si substrate that moves with a controlled speed profile. Based on surface characterisation by advanced visible-light optical metrology and several rounds of differential deposition, the surface figure of X-ray mirrors can be drastically improved.

Suitable thin film materials for differential deposition must not degrade the substrate’s surface and must develop only moderate stress levels in order to guarantee the film integrity and durability. While many metallic coatings typically exhibit increasing roughness with film thickness, WSi2 films show the opposite behaviour without significant stress build-up, making WSi2 a system of choice for figure correction by differential deposition.

Click image to enlarge

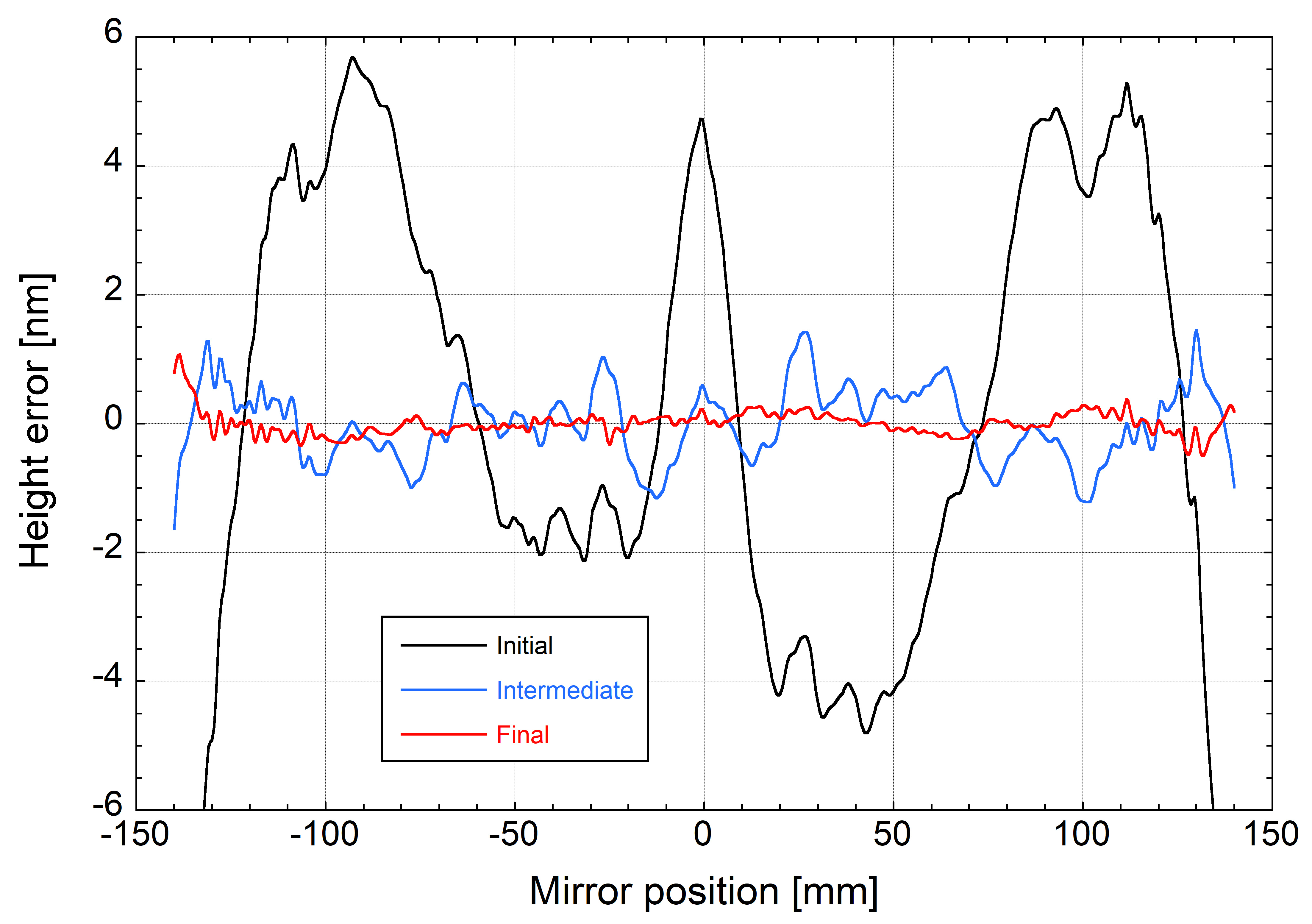

Fig. 1: Height error profile along the 300 mm-long flat Si X-ray mirror after successive corrections by differential deposition. First, long wavelength then shorter wavelength components are corrected.

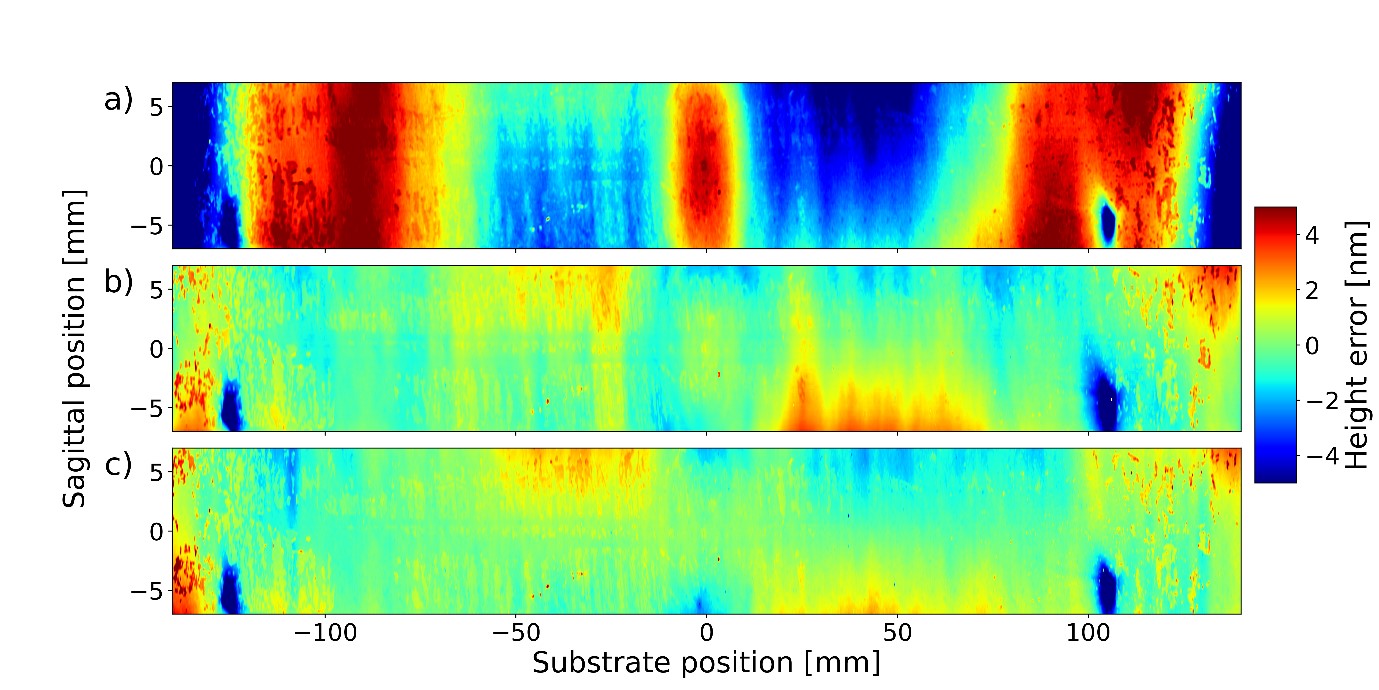

In this work, supported by the Horizon 2020 LEAPS-INNOV project, WSi2-based differential deposition was applied to a 300 mm-long flat Si X-ray mirror in several steps using appropriate flux-shaping apertures to correct for high and low wavelength components of the height error profile (Figure 1). The initial surface height errors of the X-ray mirror were reduced from 20 nm down to 1 nm peak-to-valley (Figure 2), matching the requirements of low-emittance synchrotron beamlines.

Click image to enlarge

Fig. 2: 2D surface height error profiles measured with a Fizeau interferometer for (a) the initial situation, (b) an intermediate state and (c) after the final correction.

Differential deposition using WSi2 thin films is a promising technique for significantly reducing the surface figure errors of X-ray mirrors. This technique offers the possibility to upgrade standard, affordable substrates, showing initial figure errors in the order of tens of nanometres, to sub-nanometre surface height error levels. Such mirrors are required to produce X-ray spots on the nanometre scale. Potential applications encompass synchrotron optics but also astronomy (X-ray telescopes), visible light optics and many more.

Principal publication and authors

X-ray mirrors with sub-nanometre figure errors obtained by differential deposition of thin WSi2 films, P. Bras, C. Morawe, S. Labouré, F. Perrin, A. Vivo and R. Barrett, J. Synchrotron Radiat. 30, 708-716 (2023); https://doi.org/10.1107/S1600577523003697

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement N° 101004728.

Top image: Machine used for differential deposition coating of X-ray mirrors.