- Home

- News

- General News

- Research with synchrotron...

Research with synchrotron X-rays boosts industrial innovation

12-04-2013

In February the ESRF carried out a survey of its academic users to ask about their links with industry. Replies have confirmed what we already believed, that research carried out using synchrotron X-rays is becoming increasingly beneficial to industry.

Share

Access to ESRF public beam time is granted through a peer-review process. This judges the academic quality of proposals to ensure that the most interesting and innovative experiments get selected. However, a large part of today's publication-oriented academic research also involves collaboration with industry. Sometimes this collaboration or sponsorship between an industrial company and an academic laboratory is clearly acknowledged, while in other cases such collaboration goes unnoticed. The aim of our study was therefore to quantify these links.

- 39% of the participants told us that the results of their ESRF experiment have application for industrial R&D

- 46% said that their research group has direct links or collaborations with industrial R&D centres

- 33% benefit from industrial sponsorship

At the beginning of February, the ESRF addressed the survey to 7377 scientists who had successfully submitted research proposals to the ESRF in the last 5 years. 775 replies were received: a participation of 10%. Replies came mostly from researchers at European laboratories, and a few from researchers with laboratories located in countries further afield such as America, Argentina, Brazil, India and Russia.

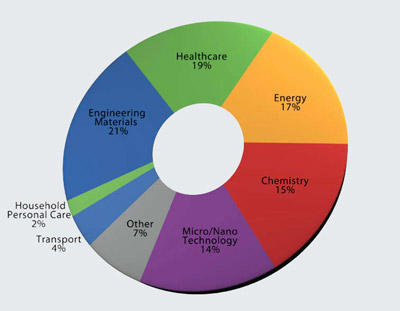

For those participants who indicated a link with industry, we asked them to tell us their industrial sector. Here a very broad spectrum surfaced with engineering materials first (21%), followed by healthcare (19%), energy (17%), chemistry (15%) and micro-/nano-technology (14%).

|

|

Figure 1. Industrial sectors represented in the ESRF user survey. |

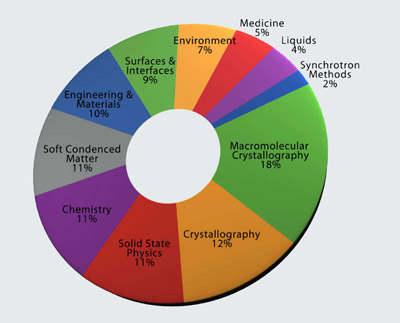

The distribution by industrial sector (Figure 1) is quite similar to the distribution of all ESRF experiments over the various science domains (Figure 2). The diversity of the domains identified would indicate that the majority of the beamlines are today involved in research linked with industry.

Figure 2. Science domains studied at the ESRF. |

What is the attraction of synchrotron X-ray studies to industrialists? Tobias Schülli, scientist in charge of the Microdiffraction Imaging Beamline, ID01, comments: “Industrialists come here because the level of detail we resolve is far superior to standard laboratory techniques. We can, for example, map the mechanical strain within micrometre-sized electronic components to identify defects. This eventually helps to fine-tune manufacturing processes. More than 50% of the experiments at ID01 concern applied materials and devices”.

The increasing use of the beamlines for industry-related research reflects a maturation of many techniques, and a shift in focus for certain beamlines. Previously, experiments also served to develop techniques and to discover their range and limits within various materials. Today, those cutting-edge experiments have become almost routine, and can be included in the portfolio of services offered to industry. An example of a newly developed technique is direct tomography. The potential of the technique was demonstrated at beamline ID16, but scientists knew it could be improved. As part of the ESRF Upgrade Programme, a new beamline is being built, ID20 - Inelastic hard X-ray scattering for electronic spectroscopy, which will permit further optimisation of the technique so that it can soon be offered to non-academic users. Scientist Simo Huotari (University of Helsinki) who pioneered direct tomography at ID16 commented, “Our novel three-dimensional X-ray imaging technique can probe the bulk distribution and chemistry of elements with low atomic number starting from lithium, and perhaps most importantly carbon and oxygen. This can be done even in large samples non-destructively. It can be used to characterise, for example, operational electrochemical cells, catalytic reactors and hydrogen storage media. It would be especially interesting to see how the pharmaceutical industry would benefit from this for characterising the three-dimensional distribution of chemicals within their products.”

Top image: Summary of the industrial collaboration survey results.