- Home

- Users & Science

- Scientific Documentation

- ESRF Highlights

- ESRF Highlights 2015

- Electronic structure, magnetism and dynamics

- A multi-technique approach to investigate silica-supported Ziegler−Natta catalysts

A multi-technique approach to investigate silica-supported Ziegler−Natta catalysts

Heterogeneous Ziegler−Natta catalysts are the most widely used catalysts for polyolefin production. A significant improvement in the definition of the structure of the active sites at a molecular level, and in the understanding of the mutual interactions among all the catalyst’s components has been achieved by using X-ray absorption and emission spectroscopy coupled with XRD, DR UV-Vis and IR laboratory techniques.

Heterogeneous Ziegler−Natta catalysts for the production of polyolefins are among the most widely used and versatile catalysts in the chemical industry and probably those having the largest impact not only in science but also in everyday life. The extraordinarily large number of polymer architectures available today and the remarkably rapid progress in polyolefin technology are closely associated with the catalyst’s development. Since their discovery in 1960s, heterogeneous Ziegler−Natta catalysts have progressed enormously, making it possible to produce advanced polyolefin materials with tailored properties. Today, Ziegler−Natta catalysis allows a precision synthesis of polyolefins based on the exact assembly of the olefin monomers on the active catalytic sites. However, Ziegler−Natta catalysts remain substantially a black box despite many efforts to understand them. The structural and electronic properties of the titanium active sites and their relation to the catalytic body as a whole are hampering the rational design of better catalysts.

|

|

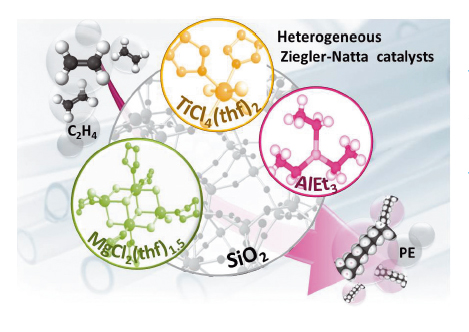

Fig. 69: Schematic representation of all the components of a silica-supported Ziegler-Natta catalyst based on titanium and magnesium chloride tetrahydrofuranates activated by an aluminum−alkyl compound. The catalyst polymerises ethylene, producing polyethylene. |

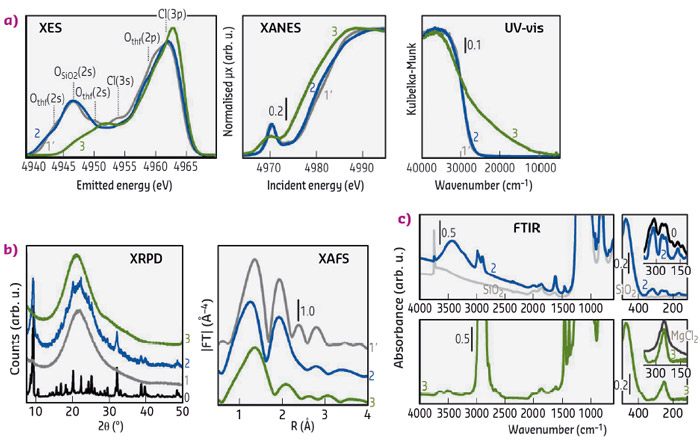

Recently, we have been involved in a systematic investigation of industrially-relevant heterogeneous Ziegler−Natta catalysts for polyethylene production that are based on titanium and magnesium chloride tetrahydrofuranates (Figure 69) [1-3]. The structural, vibrational, and electronic properties were investigated in detail by means of a multi-technique approach at each step of catalyst preparation, including pre-catalyst activation [4]. In particular, we combined in situ XAS and XES experiments (at beamlines BM26A and ID26, respectively) with XRD, DR UV-Vis and IR (both Mid-IR and Far-IR) measurements (Figure 70).

|

|

Fig. 70: (a) Electronic properties obtained by XES, XANES and DR UV-Vis, (b) structural properties obtained by XRD and EXAFS and (c) vibrational properties obtained by Mid-IR and Far-IR, of the silica support, of the SiO2/Mg (1), SiO2/Ti (1’) and SiO2/TiMg (2) pre-catalysts, and of the catalyst obtained after interaction with the aluminium-alkyl activator (3). |

It was found that in the pre-catalyst, the TiClx phase is grafted mainly to the silica surface and almost independent of the supported MgClx phase. However, the subsequent activation by means of an aluminum−alkyl compound causes important changes to both the supported MgClx phase and the TiClx phase. The resulting catalyst is entirely reconstructed. In particular, the activator removes most of the tetrahydrofuran originally present in the pre-catalyst, reduces the titanium sites and detaches most of them from the silica surface, simultaneously promoting the formation of a MgCl2 phase highly dispersed on the silica surface. The formed TiClx species are connected to the silica-supported MgCl2 phase through bridging chlorine ligands and are characterised by the presence of terminal chlorine ligands at shorter distances. Hence, the resulting active phase resembles the most famous and highly investigated Ziegler−Natta catalysts (not silica-supported), although probably much more dispersed. Moreover, the catalyst performances were monitored by means of in situ FT-IR spectroscopy, simulating industrially significant pre-polymerisation conditions.

These results demonstrate that it is now possible to achieve a complete description at a molecular level of all the constituents of Ziegler−Natta catalysts at each step of the catalyst preparation. Such a systematic investigation of all the catalyst’s components by means of a multitechnique approach might be the first fundamental step toward understanding their mutual interactions and functions down to a level of detail rarely reached by other methods, making the design of these catalysts a realistic goal for the future.

Principal publication and authors

Activation and in situ ethylene polymerization on silica-supported Ziegler−Natta catalysts, E. Groppo (a), K. Seenivasan (a), E. Gallo (a,b), A. Sommazzi (c), C. Lamberti (a,d) and S. Bordiga (a), ACS Catal. 5, 5586–5595 (2015); doi: 10.1021/acscatal.5b01108.

(a) Department of Chemistry, NIS Centre and INSTM Reference Center, University of Turin, Turin, (Italy)

(b) ESRF

(c) Versalis − Novara Research Center, Istituto Eni Donegani, Novara, (Italy)

(d) Southern Federal University, Rostov-on-Don (Russia)

References

[1] K. Seenivasan et al., Chem. Eur. J. 17, 8648−8656 (2011).

[2] E. Groppo et al., ChemCatChem 7, 1432−1437 (2015).

[3] K. Seenivasan et al., Dalton Trans. 42, 12706−12713 (2013).

[4] E. Groppo et al., Catal. Sci. Technol. 3, 858−878 (2013).